6

Scroll Enclosure Air Compressors

Operation

BEFORE START UP

1. Make sure all safety warnings, labels and instructions

have been read and understood before continuing.

2. Remove any shipping materials, brackets, etc.

3. Confi rm that the electric power source and ground have

been fi rmly connected.

4. Check the belts for tightness.

5. Be sure all pressure connections are tight.

6. Check to be certain all safety relief valves, etc., are

correctly installed.

7. Securely mount all panels and guards.

8. Check that all fuses, circuit breakers, etc., are the proper

size.

9. Make sure the inlet fi lter is properly installed.

10. Confi rm that the drain valve is closed.

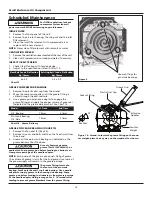

11. Visually check the rotation of the compressor pumps.

The rotation should be counterclockwise if viewing the

compressor from the pulley or belt side of the motor or

the air end. If the rotation is incorrect, have a qualifi ed

electrician correct the incomming T

1

and T

2

connections.

START-UP AND OPERATION

1. Follow all the procedures under “Before start-up” before

attempting operation of the compressor.

2. Switch on the electric source breaker.

3. Make sure electric source lamp lights up and that the

caution code or alarm code does not show up on the

display.

Note:

The alarm lamp light will come on if a temperature

sensor is not connected. If the sensor is not connected, have a

qualifi ed service person reconnect the sensor.

4. Open the discharge valve completely.

5. Push ON button and check that the compressor operates

without excessive vibration, unusual noises or leaks.

6. Close the discharge valve completely.

7. If the pressure does not rise on a three phase unit,

turn the unit off, the unit is running backwards.

Have a qualifi ed electrician switch the breaker OFF

and exchange two out of three phases of electric

source.

8. Check the discharge pressure. Also make sure the air

pressure rises to the designated pressure setting by

checking the discharge pressure gauge.

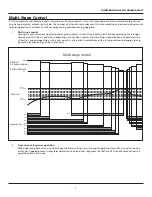

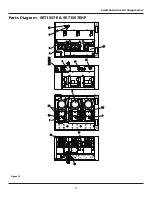

CONTROL LOGIC SEQUENCING ORDER

Since the compressors are designed using multiple air-ends,

they are using multiplex controller. The controller will start

and stop each air-end according to the pressure and air

consumption.

1) Alternating Control:

The controller will equalize the operating hours on

each air-end. It will alternate between the air end with

the most running time and the air end with the lowest

running time.

2) Prevention of long term operation:

When an air-end has been operating longer than the set-

time, the controller will alternate to the air-end with the

lowest running time. This will prevent one air end from

running continuously for too long and will equalize the

running time between the available air ends.

SHUT-DOWN

1. Stop the compressor by pushing the OFF button.

NOTE:

If the compressor rotates in reverse for more than fi ve

seconds, the check valve needs to be cleaned or replaced.

2. Switch the breaker OFF if the compressor is not to be

used for a long period of time.

STOPPING THE COMPRESSOR DURING NORMAL

OPERATION

1. Close the discharge valve.

2. Allow the air pressure to build and the compressor to

stop.

3. Turn the compressor off by pushing the OFF button.

STOPPING THE COMPRESSOR DURING EMERGENCY

OPERATION

Stop the compressor by pushing the OFF button or by turning

the power off at the main disconnect panel.

SED

SET

1

2

3

1

2

SEQ

4

3

1

2

SEH

3

1

2

(6)

3

(4)

1

(5)

2

SEO

4

3

1

2

(8)

4

1 (5)

2 (6)

3 (7)

Figure 4 - Control Logic Sequencing Order