20

Scroll Enclosure Air Compressors

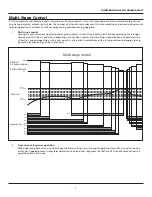

Electrical Diagram - External Operation and External Output

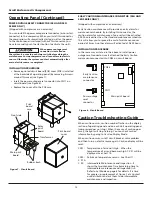

REMOTE ON / OFF SWITCH INSTRUCTIONS

1. Turn the compressor off and lockout the power to the

compressor per OSHA standards.

2. Remove the top panel from the scroll cabinet to access

the operating panel. Remove the plastic cover from the

backside of the operating panel. Lift the expansion PCB

from the operating panel.

3. Connect an external AC power source of 200 V between

terminals 1 and 2 on the expansion PCB. A switch rated

at least 200 V AC should be used. It is possible to use the

200 V AC source from the transformer on the bottom of

the cabinet.

4. The power wires should run through the right hand side

grommet when facing the front of the control panel. The

left side grommet is reserved for low voltage wires (to

reduce interference).

5. Replace the plastic cover of the operating panel. Replace

the top cover of the scroll compressor.

6. Return the power to the compressor.

7. Set the mode on the display to show external operation

mode (“ECon”).

8. The compressor should now start when external switch is

ON

, and turn off when the external switch is

OFF

.

9. Both the external switch and the control panel controls

will now turn the compressor on and off.

GENERAL FAULT DRY CONTACT CONNECTIONS

1. Turn the compressor off and lockout the power to the

compressor per OSHA standards.

2. Remove the top panel from the scroll cabinet to access

the operating panel. Remove the plastic cover from the

backside of the operating panel. Lift the expansion PCB

from the operating panel.

3. Output wires should be connected between terminals 3

and 4. The dry contacts are normally open; when there

is a fault, the contacts close. The contact rating is as

follows: 200 V AC, 1A, maximum.

4. For larger load devices such as a horn or emergency light,

a relay should be used.

5. The signal wires should run through the right hand side

grommet when facing the front of the control panel. The

left side grommet is reserved for low voltage wires (to

reduce interference).

6. Replace the plastic cover of the operating panel. Replace

the top cover of the scroll compressor.

7. Return the power to the compressor.

8. The external output will now operate when there is

either a caution or emergency. This is the default setting

for the control panel. The external output of the control

panel can be changed to only operate in case of an

emergency.

9. Reasons for Caution and Emergency stop are needed to

confi rm on the control panel display.

Self-holding

switch

AC200V

Electric source

External operation circuit

*See "ECon" in manual

External output circuit

for General Fault

Dry contact

(Normally open)

CN7

CN6

CN3

CN26

CN27

CN5

CN4

TB1

CN29

CN32

CN28

1

2

3

4

EXB

Expansion circuit board

Crimping terminal size

R1.25-3

CR 1

CN2

CN22

CN31

CN26

CN25

CN24

CN23

CN21

CN20

CN11

CN10

CN1

CN27

CN30

1A

CN13

F

DB

Display circuit board

CN1

MB

Main circuit board

Modular plug for

setting and communication

TRANS

CN12

Figure 15