Power-Flo Pumps & Systems • 877-24PUMPS • www.powerfl opumps.com

12

Outer Seal (Single & Double) -

Handle

seal parts with care. Remove c-clip (43),

seal (33) spring and rotating member

from shaft. Examine all seal parts. Inspect

contact faces for signs of uneven wear

tracks on stationary, chips and scratches

on either seal face.

DO NOT interchange

seal components, replace the entire

shaft seal (33).

Seal Plate (Double) -

Remove cap screws

(52) and washers (11) from seal plate (51).

Remove seal plate (51) and square ring

(24) from intermediate coupling (21B).

With fl at screwdriver, press out seal (33)

stationary member. Inspect square ring

(24) for cuts or abrasions.

Checking Capacitors -

Loosen gland

nut (3) and remove cap screws (22) and

washers (11) from upper housing (19).

Check motor capacitors (14) & (16) with

an Ohm meter by placing a screwdriver

across both terminals and to ground the

capacitor then remove. Connect Ohm

meter, set on high scale to terminals. If

needle moves to infi nity (∞) then drifts

back, the capacitor is good. If needle does

not move or moves to infi nity (∞) and

does not drift back, replace the capacitor.

Motor -

Remove wires from terminal

block (37) and remove cable assembly

(3) and upper housing (19). Remove

pipe plug (4) from housing (15) and

drain oil if not already done so. Position

pump upright using blocks or pvc pipe

to avoid resting pump on the shaft.

Remove retaining ring (38). Using a 1/4-20

bolt, thread bolt into the center of the

terminal block (37) and pull straight up to

removing it and o-ring (12). Disconnect all

wires, noting where each was connected.

There are numbers next to the pins on the

bottom of block, use these for reference.

Remove cap screws (35) and lockwashers

(11) from motor housing (15). Vertically

lift motor housing (15) from intermediate

coupling (21) along with square ring (20),

replace if cut or damaged. Remove stator

bolts and carefully remove stator housing

from rotor. Pull rotor out with bearing (18).

Inspect motor winding for shorts and

check resistance values. Check rotor for

wear. If rotor or the stator windings are

defective, the complete motor must be

replaced.

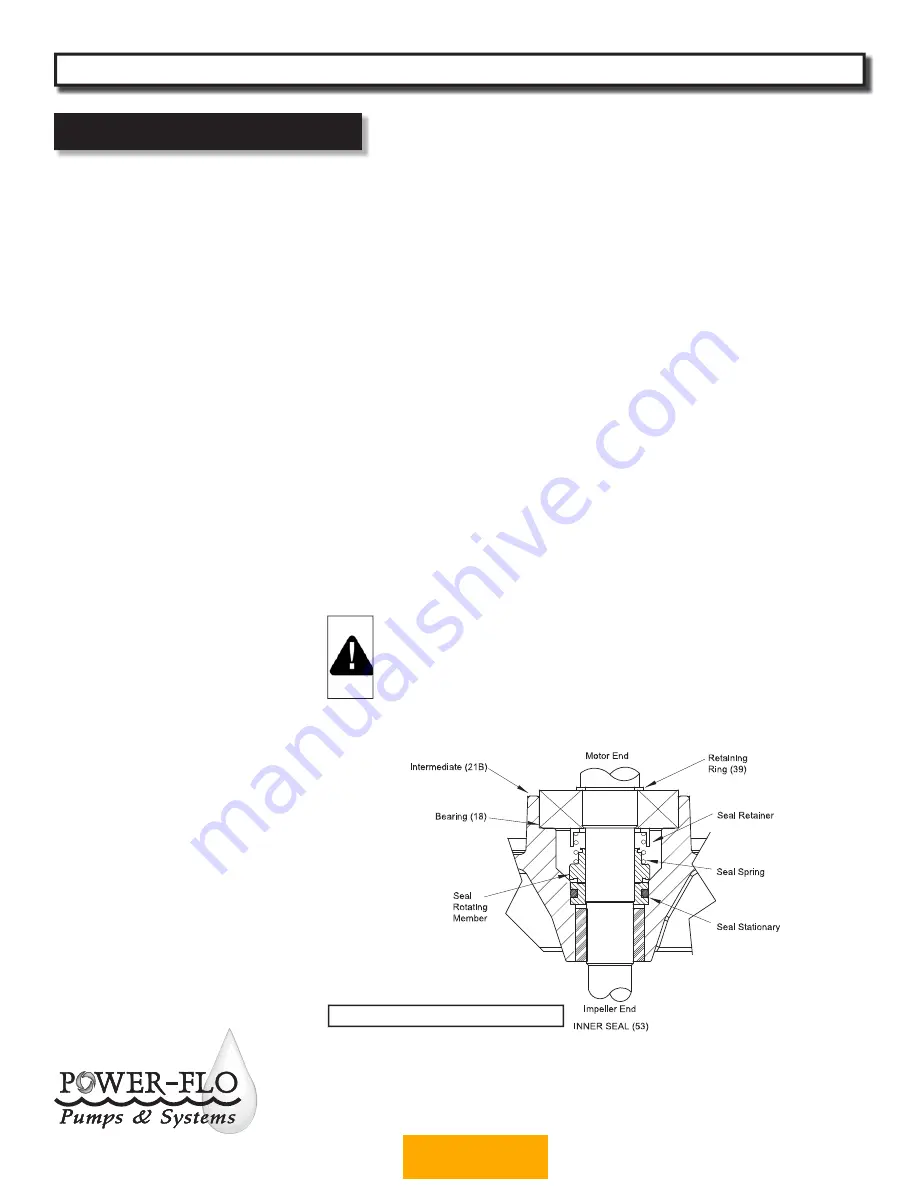

Inner Seal (Double) -

Remove seal (53)

rotating member and spring from rotor

shaft. Press stationary from intermediate

(21B) with fl at screwdriver. Examine all

seal parts. Inspect contact faces for signs

of uneven wear tracks on stationary,

chips and scratches on either seal face.

DO NOT interchange seal components,

replace the entire shaft seal (53).

Bearings -

Remove retaining ring (39)

from shaft. Using a wheel puller or arbor

press remove bearing (18) from shaft.

Remove upper motor bearing from shaft

with a bearing puller. (See Figure 5).

On Double Seal Units

, Check sleeve

bearing (23) for excessive wear, if

replacement is required, press sleeve from

intermediate coupling (21).

IMPORTANT! - All parts must be

clean before reassembly.

Handle seal parts with extreme

care. DO NOT damage lapped

surfaces.

Reassembly

Bearing -

Be careful not to damage the

rotor shaft when replacing bearing. Using

an arbor press, hold the rotor and press

the upper bearing on the rotor shaft,

applying force to the inner race of the

bearing only. Replace upper retaing ring

onto rotor shaft. In the same manner

replace lower bearing (18) onto rotor

shaft. Place lower retaining ring (39) onto

shaft.

Inner Seal (Double) -

Clean and oil seal

cavity in intermediate coupling (21B).

Lightly oil

(Do not use grease)

outer

surface of stationary member. Press

seal’s (53) stationary member firmly into

intermediate coupling (21B), using a seal

tool or pipe. Nothing should come in

contact with the seal face except the seal

tool. Be sure the stationary is in straight.

Place seal’s (53) retaining ring and spring

over shaft until seated on shaft shoulder.

Slide a bullet tool over rotor shaft

threads.

Lightly oil

(Do not use grease)

shaft,

bullet, and inner surface of bellows on

rotating member, with fi nished end away

from motor, slide rotating member over

bullet and onto shaft until it engages

spring. Make sure spring is seated in

retaining ring and spring is lined up on

rotating member and not cocked or

resting on bellows tail. (See Figure 5)

Service

PFGPC - 2HP

Submersible Grinder Pumps

Figure 5 (Double Seal Unit Shown)

BACK TO INDEX