Commissioning - Page 22

3.1 Commission the Boiler

Open Vented Systems -

Remove the pump and flush

the system thoroughly with cold water. Re-fit the pump.

Fill and vent the system then check for leaks.

Sealed Systems - Note:

The system can be filled using

a sealed system filler pump with a break tank or by any

other method approved by the Local Water Authority.

Remove the pump and flush the system thoroughly with

cold water. Re-fit the pump. Fill and vent the system

until the pressure gauge registers 1.5 bar (21.5 lbf/in²)

and check for leaks. Raise the pressure until the safety

valve lifts, this should occur within ± 0.3 bar of the preset

lift pressure of 3 bar. Release water to attain the correct

cold fill pressure.

All Systems

Warning: Before lighting the boiler, ensure that the

outer white case has been correctly fitted and that

the sealing strip fitted to the outer white case is

forming a tight seal with the main boiler chassis.

The controls cover is left off at this stage.

Preliminary electrical system checks. These checks

must be carried out before attempting to light the boiler.

They are:-

Earth Continuity, Short Circuit, Polarity

& Resistance to Earth.

1)

The whole of the gas installation must be checked for

soundness and purged in accordance with BS 6891.

2)

Set the boiler temperature control knob to 'O' Standby.

3)

Turn the boiler gas service cock to the 'On' position and

that the main gas supply is turned 'On'.

4)

Make sure that the system is full of water and that the

pump and radiator isolating valves are open. Vent air

from the system.

5)

Ensure that the main electricity supply is 'On'.

6)

Check that the time control, if fitted, is in an 'On' position

and that the room and cylinder thermostat, where fitted

are set to high temperatures.

First time lighting:

7)

Set the temperature control knob to its maximum setting.

The boiler will attempt to light, if the boiler does not light

within 3 attempts (due to air in the system) the boiler controls

will go to 'Lockout' and the upper Red LED on the control

panel will go to a rapid flashing mode. To re-start the lighting

sequence press the reset button on the control panel. There

will be a short delay before the lighting sequence starts.

When the boiler burner flame has established and the

burner lights the lower Green LED on the user control

panel will be on continuously.

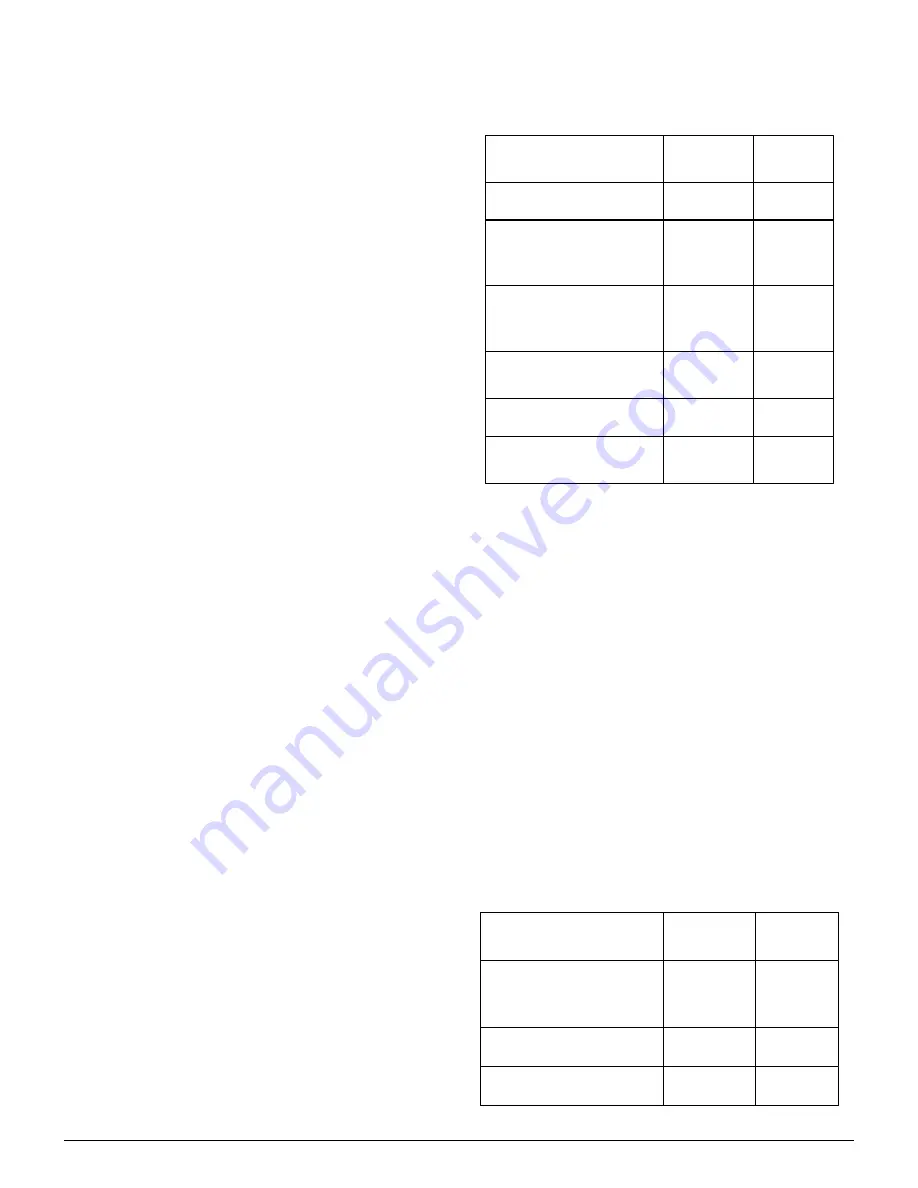

LED Indicators

Status

Green LED

Red LED

Mains ON Only

OFF

ON

Ext. Call for Heat

(Boiler set to STNDBY

Temp. Control set to 'O' Off)

FLASHING

2 Per Sec.

ON

Ext. Call for Heat

(STNDBY switch to ON,

Temp. Control set to Max.)

FLASHING

2 Per Sec.

OFF

Ignition

(i.e. Gas and Sparks ON)

FLASHING

16 Per Sec.

OFF

Boiler Temperature

Control Satisfied

FLASHING

2 Per Sec.

ON

FLAME Detected

ON

OFF

8)

With the main burner running, check for gas

soundness using leak detection fluid.

9)

Allow the system to reach maximum working

temperature and examine for water leaks. Set the

temperature control to 'Standby' and drain the

system whilst still hot.

10) Re-fill and vent the system making a final check for

leaks.

On sealed systems adjust to the correct cold fill

pressure. Set the pressure gauge pointer to the system

design pressure.

If a by-pass circuit is fitted the by-pass valve should be

adjusted with the boiler operating under minimum load

conditions to maintain sufficient water flow through the

boiler to ensure that the overheat thermostat does not

operate under normal conditions.

If the boiler fails to operate

Check the LED indicator fault modes below and refer to

fault finding guide and boiler wiring diagram.

LED Indicators Fault Modes

Status

Green LED

Red LED

Blocking -

Mains Frequency

incorrect or Air Switch

Fault

>1 min. or

Reset

button held

in to force a restart

ON

FLASHING

2 Per Sec.

Earth Fault

or

Mains Reversal

FLASHING

2 Per Sec.

FLASHING

2 Per Sec.

Lockout

OFF

FLASHING

2 Per Sec.

Summary of Contents for Suprima 30

Page 6: ...Installation Requirements Page 6 ...

Page 10: ...Installation Requirements Page 10 Fig 3 Fig 4 ...

Page 12: ...Flue Kits Page 12 ...

Page 13: ...Optional Extras Flues Page 13 Installation instructions included as necessary with each kit ...

Page 14: ...System and Other Kits Page 14 ...

Page 15: ...System and other Kits Page 15 ...

Page 33: ...6 Wiring Diagram Page 33 ...