29

3.8.7.

Removing and fitting the crankshaft seal – crankshaft side

3.8.7.1.

Special tools

Porsche Motorsport recommends use of the following special tools to

remove and fit the flywheel side crankshaft seal:

Pressure pad:

000.721.912.60

Seal extractor jig:

000.721.971.90

3.8.7.2.

Removal

1.

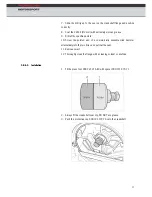

Drill two holes (Ø 2,5 mm), 180° opposed from one another, into the

metal ring of the crankshaft seal. Never lever out the seal!

2.

Screw the threaded end of a commercially available slide-hammer

alternatively into the holes and extract the metal ring evenly.

Summary of Contents for 911 GT3R 2010

Page 1: ...Technical Manual Model 2010...

Page 10: ...7 3 3 Engine power and torque curves...

Page 44: ...41 4 3 Exhaust system 4 3 1 Standard system 4 3 2 Catalytic converter 100 cells...

Page 45: ...42...

Page 79: ...76 rm 6 3 2 4 Trailing a 8 mm Buchse 28 mm Buchse...

Page 107: ...104 r 9 2 1 Front bumper 9 2 Exterio...

Page 108: ...105 9 3 Rear wing P1 P12 Left wing support Gurney 10mm...

Page 139: ...136 10 12 Relay and fuse ass 10 12 1 Fuse holder ignment...

Page 141: ...138 10 12 4 MS4 sensor system...