9

EGW06-PCPEG-20140813

TM

TM

ROOM DEW POINT CONTROL

PoolPak™ units with the ECC-PCP controller operate using an advanced type of control called dew point temperature

control. This method of control is more accurate than conventional relative humidity control. The main purpose of a

dehumidification system is to maintain the amount of moisture in the pool area below a level that would cause damage

to the building. Relative humidity is a measurement of the percentage of moisture which is in the air at a given dry

bulb temperature in proportion to the maximum amount of moisture that could be contained at this particular dry bulb

temperature. Warmer air can hold more moisture than colder air and, therefore, changes in dry bulb temperature will

change the relative humidity reading without any change in the actual amount of moisture in the air. The amount of

moisture in the air is expressed as “grains of moisture per pound of dry air” and is directly related to the dew point

temperature.

The ECC-PCP uses dew point control to operate the PoolPak™ unit and maintain the moisture level below the setpoint.

The space dry bulb temperature and relative humidity determine the dew point temperature. By varying the space

temperature and space relative humidity set points, the dew point set point is changed. When the space dew point

temperature rises more than 1/2 degree Fahrenheit above the space dew point temperature set point, the ECC-PCP

controller energizes the compressor for dehumidification. As the dew point temperature drops more than 1/2 degree

Fahrenheit below the dew point temperature set point the controller de-energizes the compressor.

POOLCOMPAK OPERATION

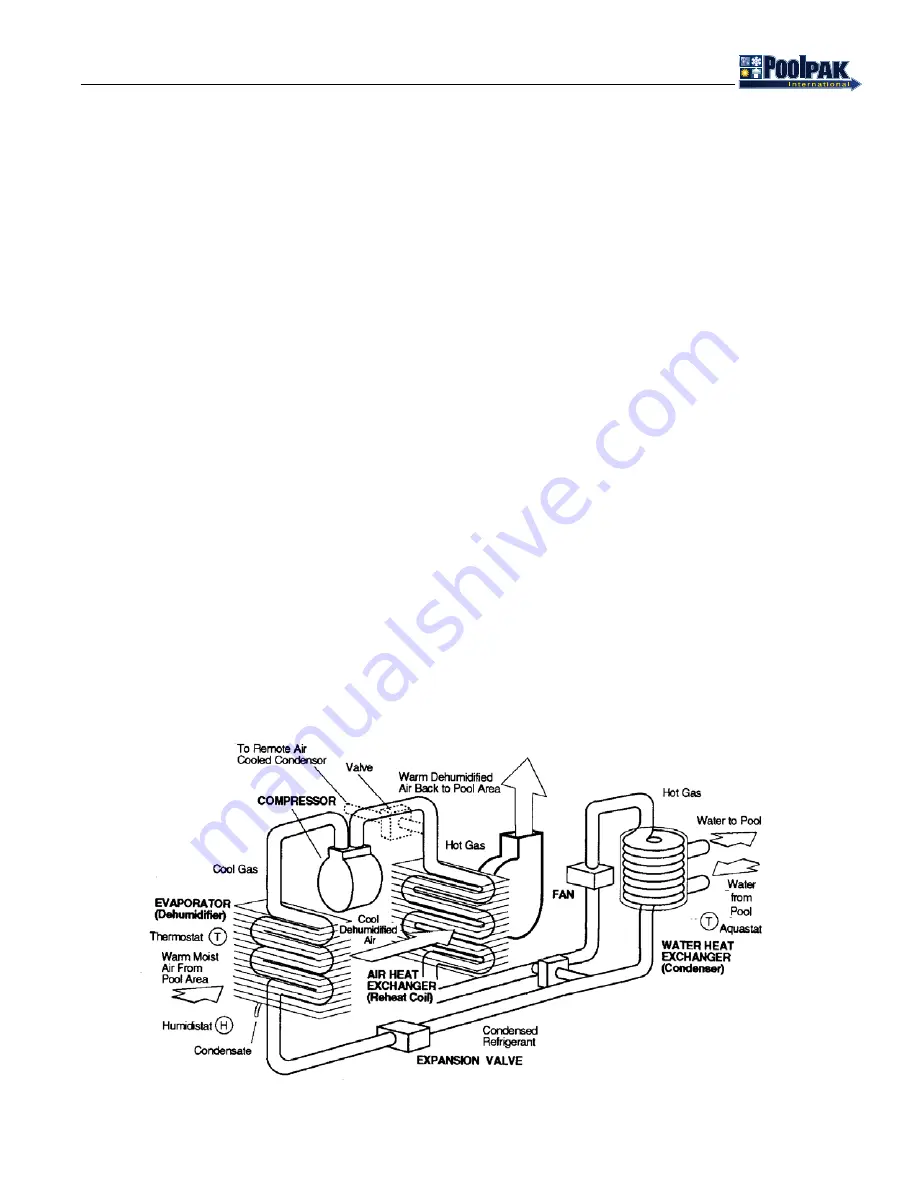

The PoolComPak™ fan draws in warm, moist air from the pool enclosure. This air passes through the evaporator

(dehumidification) coil and gives up heat energy to the refrigerant which is in a cool, liquid state. This exchange of

energy causes the air temperature to fall below its dew point, resulting in moisture condensation on the evaporator coil.

The moisture formed falls into the unit’s condensate drain pan. After passing through the evaporator coil, the refrigerant

becomes a cool gas.

The refrigerant enters the unit’s compressor, where it is compressed into a hot gas. While in the compressor, the

refrigerant absorbs the energy used to operate the compressor. This hot gas refrigerant then travels either through an air

reheat coil, the pool water condenser or to an optional auxiliary air conditioning condenser, which may be either air or

water cooled. If air heating is called for, the air reheat coil is used. The hot refrigerant exchanges energy with the cooler,

dehumidified air coming from the evaporator coil. This causes the temperature of the air to rise for heating.

Figure 2-1. PoolComPak™ AW and HCD Typical Refrigerant System Schematic

PCP_EG_Schematic3D_20121204.tif

Section II: Principles, Functions, and Features