● You should now be ready to actually remove the nozzle. It’s going to be hot, so again,

make sure the paper towel is in place on the print bed, because if the nozzle drops the

paper towel will prevent it from melting the tape where it lands.

● Here’s the one tricky and important part:

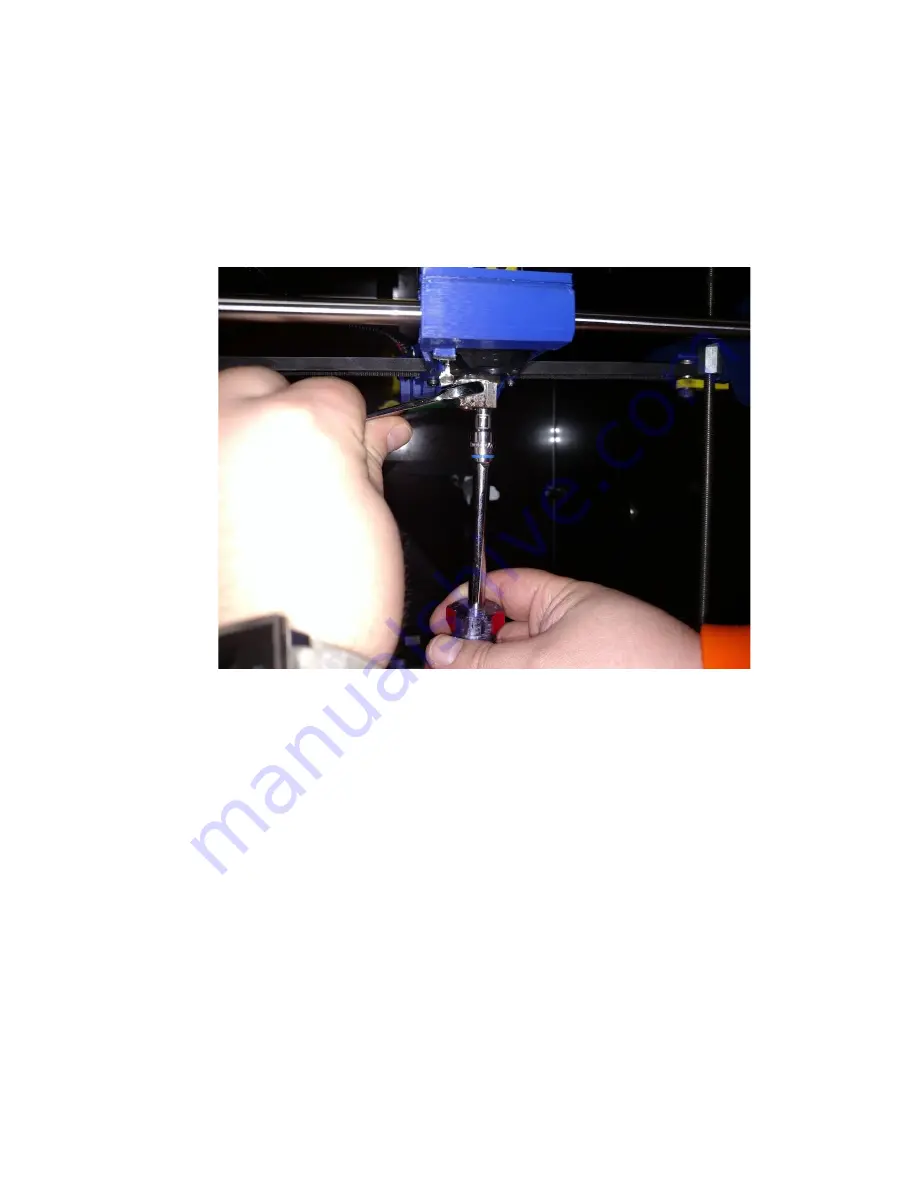

○ Slide the 13 mm open end wrench onto the aluminum block from the left. Slip the

7 mm nut driver onto the nozzle. (If you have a good feel for and experience with

this type of thing, feel free to use different orientations.)

○ The purpose of the wrench is to counter the twisting force on the aluminum block

(and therefore the relatively delicate Filament Tube) that will be applied to it

through the effort of loosening the nozzle. All you need to do is keep it from trying

to twist. You will therefore resist the nozzle-twisting force with a matching force.

○ If you take a long time with these next steps, the wrench will become too hot to

work with and you will need to remove it and wait for it to cool down before trying

again.

○ The nut driver on the nozzle needs to rotate with the near side traveling toward

your left. Slowly apply a twisting torque on the nozzle. Match that twisting force

using the 13mm wrench - thumb pressing near the aluminum block, fingers

pulling on the left end.

○ The nozzle should fairly easily break free and become easy to turn. At that point,

you can remove the 13mm wrench, and also turn off the head heat.

○ Spin the 7 mm nut driver a few times to remove the nozzle. Just leave it in the

end of the nut driver to cool down. Do not try to remove it until it has cooled down

- the nozzle will burn you if you try to grab it.

Installing the new nozzle

18