Pre-installation requirements

The sub floor must be swept clean and be free from mortar residues.

Installation

Laying the floating floor panels

Step 1:

Lay the 1200 x 1200 x 50mm floating floor panels directly over

the entire floor area to be heated, ensuring the panel grooves are

aligned. The panels can be cut to fit where necessary.

A void in the insulation is often retained around the edge of the

room to allow for distribution pipes to be laid from the room

to the manifold.

Laying the spreader plates

Step 2:

Single heat spreader plates that have pre-formed grooves at

300mm centres need to be laid on top of the floating floor panels.

These plates ensure an even spread of heat across the floor area

and hold the pipe firmly within place in the floating floor panel.

Laying the pipe

Step 3:

Once you have completed laying the floating floor panels and heat

spreader plates the pipe can be fitted into the pre-formed grooves of

the heat spreader plate. Start at the manifold position and use the

grooves in the floating floor panel to loop round the entire room.

The maximum circuit length is 80m using 15mm pipe or 100m

using 18mm pipe. Pipe should be laid in the pattern shown below.

NOTE:

Areas of potential high point loading, e.g. under heavy

furniture kitchen units and appliances, will require additional floor

support. Timber battens (50mm x 50mm) should be positioned

between the floating floor panels and notched to allow the passage

of pipes.

Testing

Step 4:

Once the pipe circuits have been installed and connected to the

manifold the system should be pressure tested to 6 bar for a

minimum of 1 hour before the timber floor covering is laid. It is

recommended that the system remains under pressure whilst the

flooring is laid.

Finishing

The room can then be finished by fitting 18mm or 22mm tongue and

groove sheets of chipboard, glued on the edge, over the floating floor

system. Mark the position of the pipe where door thresholds or carpet

strip are to be installed.

When laying a ceramic or stone floor covering ensure that any

deflection in the floor is minimised. It is recommended that a slip mat

or uncoupling membrane is used rather than a second layer of wood.

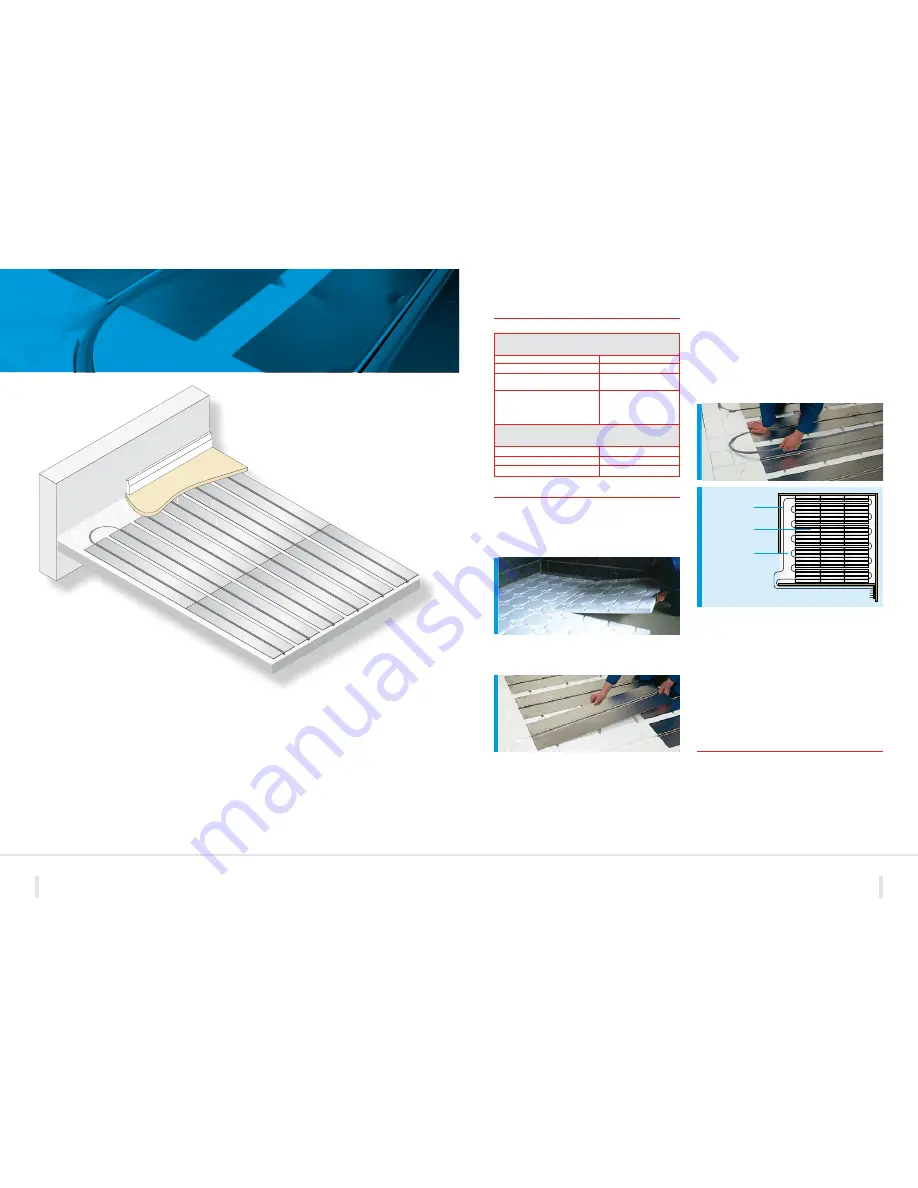

The Polypipe floating floor system is designed for use in applications where a solid

floor installation is not suitable due to structural weight limitations or where a

‘dry build’ floor option is required. Suitable for use in either new build or existing

properties, the floating floor panels can be installed directly on top of both solid

and timber floors.

The 50mm thick high density polystyrene panels have a

thermal value of 0.036W/mK and can be used to enhance

the thermal insulation requirement of the floor structure as

required under current Building Regulations. However, care

should be taken when installing floating floor panels on top

of a primary insulation layer to ensure that excessive deflection

does not occur in the final floor construction.

It is therefore recommended that any other insulation

materials used below the floating floor panels are of a high

density construction (100kN/m

2

@ 10% compression min).

16

17

FLOATING FLOOR

Key design and installation information

Pipe

3.1m/m

2

at 300mm centres

Floating floor panel

1 panel/1.4m

2

Single spreader plate

3 plates/m

2

Material requirements (approx)

Maximum heat output

Approx.

70W/m

2

Recommended design flow temp

60°C

Maximum circuit length

80m (15mm pipe)

100m (18mm pipe)

Maximum coverage per circuit

25.8m

2

at 300mm centres

(15mm pipe)

30m

2

at 300mm centres

(18mm pipe)

Polyplumb

barrier pipe

Single heat

spreader plate

Insulated floating

floor panel