ELECTRICAL

10.25

CONVENTIONAL BATTERY

OFF SEASON STORAGE

To prevent battery damage during extended periods

of non-use, the following basic battery maintenance

items must be performed:

G

Remove the battery from the machine

and wash the case and battery tray

with a mild solution of baking soda

and water. Rinse with lots of fresh

water after cleaning. NOTE: Do not

get any of the baking soda into the

battery or the acid will be neutralized.

G

Using a wire brush or knife, remove any

corrosion

from

the

cables

and

terminals.

G

Make sure that the electrolyte is at the

proper level. Add distilled water if

necessary.

G

Charge at a rate no greater than 1/10 of

the battery’s amp/hr capacity until

the

electrolyte’s

specific

gravity

reaches 1.270 or greater.

G

Store the battery either in the machine

with the cables disconnected, or

store in a cool place.

NOTE: Stored batteries lose their charge at the rate

of 1% per day. Recharge to full capacity every 30 to

60 days during a non-use period. If the battery is

stored during the winter months, electrolyte will freeze

at higher temperatures as the battery discharges.

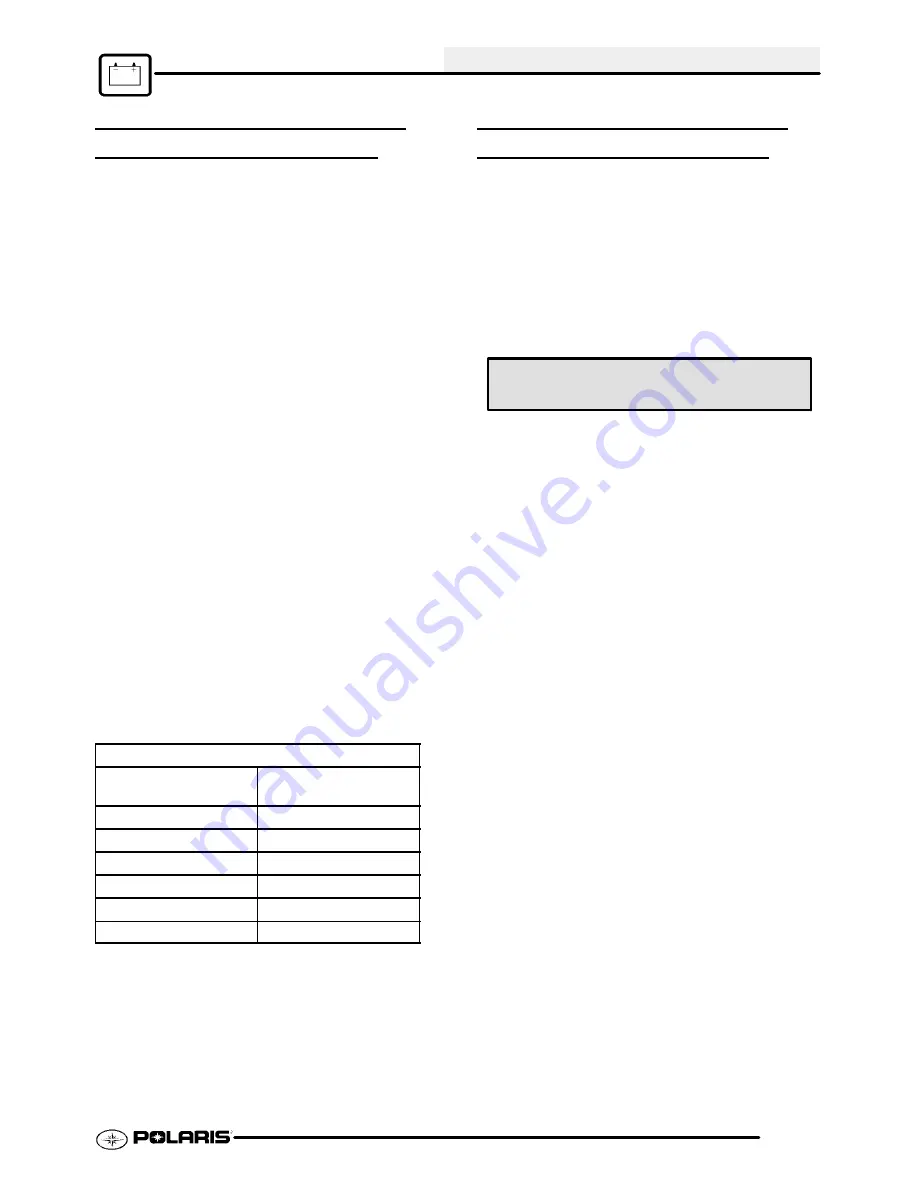

The chart below indicates freezing points by specific

gravity.

Electrolyte Freezing Points

Specific Gravity

of Electrolyte

Freezing

Point

1.265

-75

°

F

1.225

-35

°

F

1.200

-17

°

F

1.150

+5

°

F

1.100

+18

°

F

1.050

+27

°

F

CONVENTIONAL BATTERY

CHARGING PROCEDURE

1.

Remove the battery from the ATV to prevent

damage from leaking or spilled acid during

charging.

2.

Charge the battery with a charging output no

larger than 1/10 of the battery’s amp/hr rating.

Charge as needed to raise the specific gravity to

1.270 or greater.

3.

Install battery in vehicle with positive terminal

toward the front. Coat threads of battery bolt with

a corrosion resistant dielectric grease.

Dielectric Grease

(PN 2871329)

4.

Connect battery cables.

WARNING!:

To avoid the possibility of sparks and/or

explosion, connect positive (red) cable first and

negative (black) cable last.

5.

After connecting the battery cables, install the

cover on the battery and attach the hold down

strap.

6.

Install clear battery vent tube from vehicle to

battery vent. WARNING: Vent tube must be free

from obstructions and kinks

and securely

installed. If not, battery gases could accumulate

and cause an explosion. Vent should be routed

away from frame and body to prevent contact with

electrolyte. Avoid skin contact with electrolyte, as

severe burns could result. If electrolyte contacts

the vehicle frame, corrosion will occur.

7.

Route cables so they are tucked away in front and

behind battery.

8.

Reinstall battery, attaching positive (+) (red) cable

first and then the negative (-) (black) cable. Coat

terminals and bolt threads with Dielectric Grease

(PN 2871329).

9.

(Conventional Lead/Acid Batteries Only) Install

clear battery vent tube from vehicle to battery vent.

WARNING:

Vent tube must be free from

obstructions and kinks and securely installed. If not,

battery gases could accumulate and cause an

explosion. Vent should be routed away from frame

and body to prevent contact with electrolyte. Avoid

skin contact with battery electrolyte, severe burns

could result.

If electrolyte contacts the vehicle

frame, corrosion will occur.

10. Route cables so they are tucked away in front and

behind battery.

11. Reinstall battery cover and holder strap.

PartShark.com

877-999-5686

Summary of Contents for 2009 Trail Blazer 330

Page 94: ...ENGINE 3 48 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 110: ...FUEL SYSTEM CARBURETION 4 16 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 124: ...BODY STEERING SUSPENSION 5 14 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 196: ...ELECTRICAL 10 4 REVERSE LIMIT SYSTEM P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 226: ...ELECTRICAL 10 34 NOTES P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

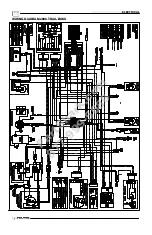

Page 227: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BOSS P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 228: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BOSS P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

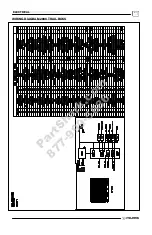

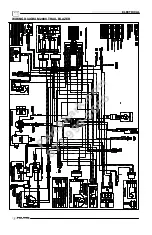

Page 229: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BLAZER P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...

Page 230: ...ELECTRICAL WIRING DIAGRAM 2009 TRAIL BLAZER P a r t S h a r k c o m 8 7 7 9 9 9 5 6 8 6 ...