12

Pub. No. OM-A-10E — April 2004

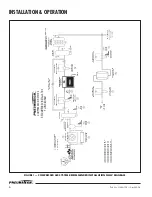

FIGURE 3 — PE & EE SERIES FLOW DIAGRAM

S

27

EX

6

5

25

EX

EX

28

S

6

5

AIR

OPEN

2

CLOSED

OPEN

2

1

CLOSED

3

OPEN

3

AIR OUTLET

CLOSED

13

TH

INLET

9

8

9

1

EX (SLIGHT BLEED)

CLOSED

18

S

29

EX

17

TH

TH

16

4

CLOSED

OPEN

4

22

23

24

21

20

19

PS1

14

15

13

TH

7

12

11

9

7

12

8

9

PILOT AIR LINE

9

ES

ES

ES

ES

ES

ES

ES

ES

TYPICAL PE SERIES

FLOW DIAGRAM

1.

PRESSURE VESSEL

2.

AIR INLET VALVE

3.

AIR OUTLET CHECK VALVE

4.

PURGE FLOW CHECK VALVE

5.

PURGE VALVE

7.

DESICCANT FILL PORT

8.

DESICCANT DRAIN PORT

9.

DESICCANT SCREEN

10. PRESSURE RELIEF VALVE

12. TEMPERATURE GAUGE

14. ELECTRIC HEATER

15. HEATER CHAMBER

16. HEATER CONTROL THERMOSTAT

17. OVER TEMPERATURE THERMOSTAT

18. PURGE ISOLATION VALVE (OPTIONAL)

19. PURGE ORIFICE ASSEMBLY

20. PURGE ADJUSTMENT PRESSURE GAUGE

22. PILOT AIR SHUT-OFF VALVE

23. PILOT AIR FILTER

24. MOISTURE INDICATOR (OPTIONAL)

25. 4 WAY LEFT TOWER SWITCHING SOLENOID

27. 4 WAY LEFT TOWER PURGE SOLENOID

29. 4 WAY PURGE ISOLATION

SOLENOID (OPTIONAL)

1. THIS PROCESS & INSTRUMENT DRAWING IS NOT AN ISOMETRIC DRAWING,

THE RELATIVE POSITION OF VARIOUS EQUIPMENT IS PURELY SCHEMATIC.

2. VALVE POSITION SHOWN IN THIS DRAWING IS AT DRYER OPERATION

THROUGH THE RIGHT TOWER.

EX -

EXHAUST

ES -

ELECTRICAL SIGNAL

PS1 - LOW PRESSURE SWITCH

PS2 - PURGE ISOLATION PRESSURE SWITCH (OPTIONAL)

FLOW

REGEN

FLOW

DRYING