14

Pub. No. OM-A-10E — April 2004

9.

Slowly open the dryer outlet isolation valve to

pressurize the downstream system.

10. Use the manual advance button to cycle the dryer

through the valve sequences.

Adjustments & Settings

1.

At start-up note the blower pressure. The intake filter

should be changed when there is a significant drop

in blower pressure.

2.

Adjust the cooling flow pressure at the recommended

level ______ PSIG.

3.

Set heater thermostat TH1. 390°F (Located in the

bottom of the heater shell)

4.

Set over temperature thermostat TH2. 200°F.

(Located in the top of the heater shell)

5.

Set desiccant bed thermostat TH3/TH4. 250°F.

6.

Set heater failure thermostat TH5. 300°F. (Located in

the bottom of the heater shell) Optional

7.

Set heater failure time delay relay 3 HRS. Optional

8.

Set failure to shift time delay relay 5 HRS. Optional

9.

Check and set the dewpoint monitor Setpoint

Settings. Settings are factory preset. See dewpoint

display setting on Page 19.

10. Open the bleed valve on the optional dewpoint

sensor probe.

11. Dewpoint Demand Setpoint (SP1): ______

12. High Humidity Alarm Setpoint (SP2): ______

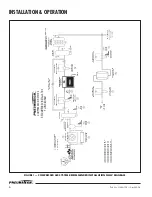

Sequence of Operation

The sequence of operation of the External Heat

Reactivated Blower Purge Dryer can be readily followed

by referring to the following flow schematic and timing

sequence.

During initial start-up with the power switch in the OFF

position, and the towers pressurized with air, both inlet

valves stay in the OPEN position and the purge valves stay

in the CLOSED position. This type of fail safe valve

operation allows the air to dry through both the towers,

without any purge in the event of loss of power to dryer.

This will give you extended drying time until desiccant

chambers are saturated.

The desiccant is designed to handle air saturated with

water vapor only. Any liquids or slugs of water tend to

decrease the efficiency of the desiccant and retard the

regeneration process to provide the designed dewpoint.

With the power switch in the ON position at

time equal to 0.0 hrs.,

the left tower air inlet valve is

open to allow the air to pass through the left tower. The

right tower inlet valve is closed. The saturated compressed

air/gas passes through the desiccant in the left tower

where the desiccant adsorbs the moisture, and the dry air

at a pressure dewpoint of -40°F or less exits through the

left outlet check valve and goes out into the plant air

system through the afterfilter.

At time equal to 5 minutes,

the right tower purge

valve depressurizes the right tower so that the desiccant is

not disturbed.

At time equal to 10 minutes,

the blower and heater

are energized to commence the regeneration cycle.

The temperature of the purge air is controlled by the

heater control thermostats to maintain the preset

temperature. During the heating cycle, the bed

temperature should rise to 250°F (121°C) in

approximately two hours. The heater control thermostats

will cycle the heater to maintain this 250°F bed

temperature. The hot purge air passes through the right

purge flow check valve and enters the desiccant bed at the

top of the tower. The hot purge air removes the previously

adsorbed water vapor from the desiccant and purges out

through the right purge valve, and is exhausted into the

atmosphere through the exhaust muffler.

NOTE:

During the regeneration air flow through the

desiccant bed, the tower pressure gauge should read 0

PSIG. Any higher pressure is an indication of a plugged

muffler, which will retard the regeneration of desiccant. In

the event of a leaking valve or check valve a back

pressure will develop. A significant back pressure will

cause the blower amps to increase and kick off the blower

on high overloads.

At time equal to 3 hrs.,

the blower and heater are de-

energized, and the cooling flow valve opens to start the

cooling cycle to reduce the temperature in the desiccant

bed and prepare it for the drying cycle.

NOTE:

As soon as the cooling cycle begins, adjust the

purge adjustment valve to the recommended purge control

setting. This adjustment should only be required once, and

then the locking mechanism should be locked in place.