33

33

9

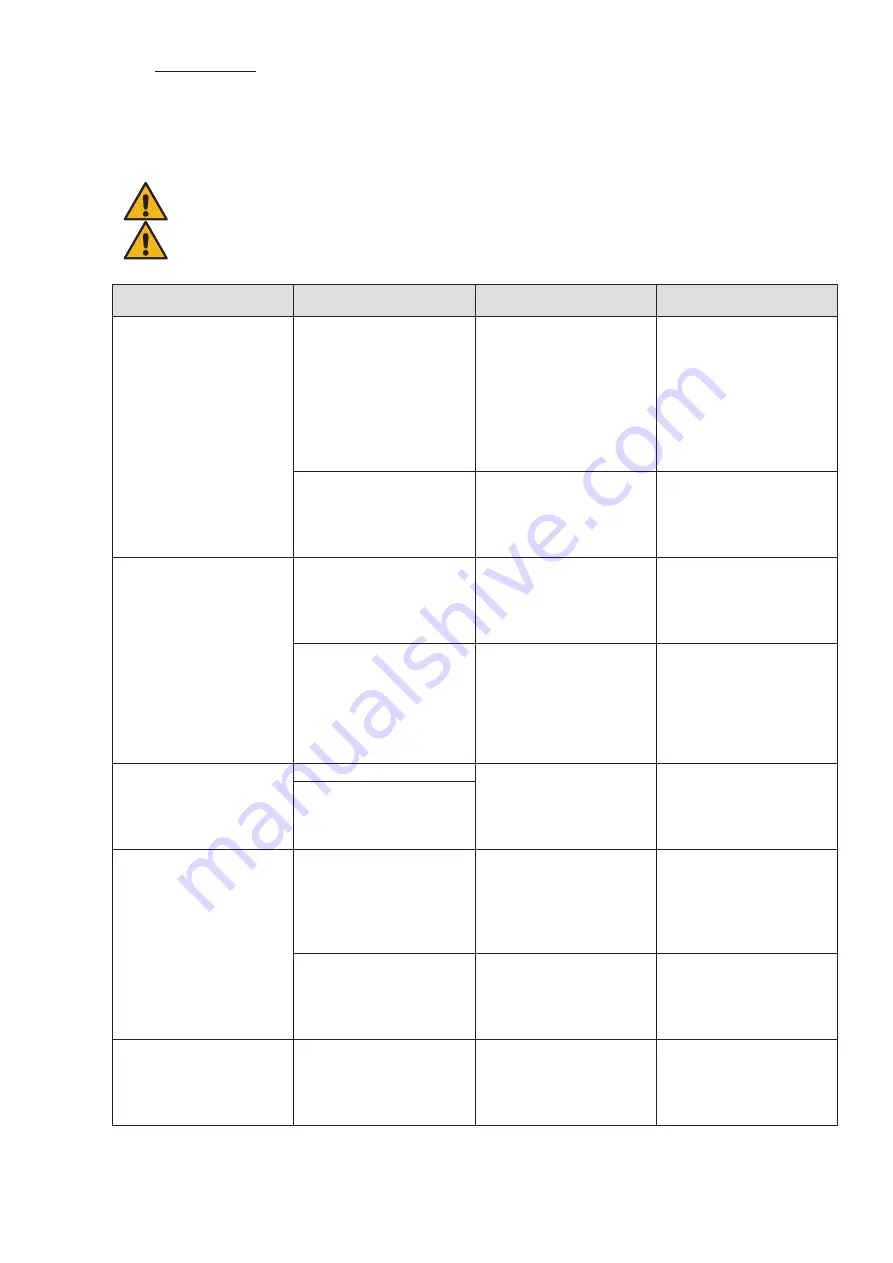

Malfunctions

Hoist trolley units last very long without malfunctions when maintenance is regularly preformed,

but malfunctions are is unavoidable. Below table shows malfunctions which might occur.

-

When a malfunction has been found it has to be reported immediately, to the

owner, who has to initiate repair work, which is to be carried out by competent

maintenance personnel.

-

All malfunctions and repairs must be written in a logbook.

-

Warning!

Repair work may only be performed when the equipment is out of

service.

-

Warning!

Parts must always be replaced when damage occurs that directly or

indirectly endangers the safety of the hoist.

Malfunction

Cause

Explanation

Remedy

The pawl makes a

proper clicking sound

but fails to lift the

load.

Worn friction plates.

When the hoist is

frequently used, the

friction plates will

wear. This results in

gaps between the

friction disk, bushing

and hand chain wheel

causing the brake to

slip.

Replace the friction

plates and bushing.

The braking surface is

dirty or oily causing

the load to slip.

The braking surface

shall be clean and free

of lubricants because it

is a dry-type brake.

Clean the braking

surface or if

necessary, replace the

brake and its

components.

The pawl cannot be

heard and fails to lift

the load.

The pawl has been

improperly assembled.

If the pawl is

assembled incorrectly,

it will not properly

mesh with the ratchet

disk.

Reassemble the pawl

and its components.

The pawl is not moving

smoothly.

Dirt has accumulated

on the grease of the

pawl and pawl shaft.

Movement will become

sluggish or the pawl

remains stuck in the

kicked out position.

Reassemble the pawl

and its components

and replace the

lubricant.

Excessive hand chain

force is needed to lift

the load. A squeaking

noise can possibly be

heard.

Worn gear teeth.

Dirt has accumulated

resulting in wear,

damage and improper

meshing of gears.

Replace the pinion,

gear, load gear, gear

case, side plate and

bearings.

Worn or damaged

bearing.

Jerky lowering or

excessive hand chain

force is needed to

lower the load.

The brake is too tight.

As a result of a shock

during operation or

because a load was

suspended for a long

period of time, the

brake tightened.

Free the brake forcibly

by jerking the hand

chain.

The brake is rusted.

The brake hasn’t be

cleaned correctly

during maintenance.

Clean the braking

surface or if

necessary, replace the

brake and its

components.

The hoist drops the

load immediately when

lowering is started.

The braking surface is

dirty or oily causing

the load to slip.

The braking surface

shall be clean and free

of lubricants because it

is a dry-type brake.

Clean the braking

surface or if

necessary, replace the

brake and its

components.

Summary of Contents for PKB Series

Page 44: ...44 10 ton N100 16 ton N160 44 ...

Page 45: ...45 20 ton N200 25 ton N250 45 ...