Picote Solutions Oy Ltd

22

www.picoteinstitute.com

STEP 1

STEP 2

** If coating pipe diameters > DN150 (6") use the Picote Maxi Coating Pump

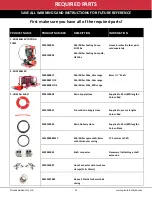

Select the appropriate brush size for the pipe.

Always use a brush one

pipe size larger than the pipe to be coated.

Note: Although one brush can be used in straight pipe, dual brushes are

required for pipes with bends or transitions.

Always use a sleeve on the outer casing of the miller shaft. Attach the smaller brush

against the sleeve leaving roughly 6mm /

1

/4

”

between the brush hub and sleeve and

tighten the two 2.5mm set screws.

DO NOT OVER TIGHTEN OR SCREWS MAY STRIP THE NYLON HUB.

Recommended Coating Brush Diameters (Mini Cleaner / Mini Miller)

Host Pipe

Diameter

Front Coating Brush

Diameter (Straight)

Front Coating Brush

Diameter (Multiple Bends)

Rear Coating

Brush

Distance Between

Brushes

DN32 (1.

1

/

4

”)

50mm

(2”)

N/A

N/A

N/A

DN40 (1.

1

/

2

”)

50mm

(2”)

50mm

(2”)

50mm (2")

40mm (1.

1

/

2

”)

DN50

(2”)

75mm

(3”)

100mm

(4”)

50mm

(2”)

50mm

(2”)

DN70

(3”)

100mm

(4”)

125mm

(5”)

75mm

(3”)

75mm

(3”)

DN100

(4”)

125mm

(5”)

175mm

(7”)

100mm

(4”)

100mm

(4”)

DN150

(6”)

175mm

(7”)

220mm

(9”)

150mm

(6”)

150mm

(6”)

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

COATING SYSTEM ASSEMBLY | BRUSHES cont.

22

Recommended Coating Brush Diameters (Midi Miller / Midi Cleaner / Super Midi Miller / Maxi Miller)

Host Pipe

Diameter

Front Coating Brush

Diameter (Straight)

Front Coating Brush

Diameter (Multiple Bends)

Rear Coating

Brush

Distance Between

Brushes

DN70

(3”)

100mm

(4”)

125mm

(5”)

100mm

(4”)

25

-

50mm

(1

-

2”)

DN100

(4”)

150mm

(6”)

175mm

(7”)

150mm

(6”)

25

-

50mm

(1

-

2”)

DN150

(6”)

175mm

(7”)

200mm

(8”)

175mm

(7”)

25

-

50mm

(1

-

2”)