CON

TENTS

Scraper

Ratchet Socket Wrench

Vat Nut Socket

Allen Key

Funnel

Paper Strainer x 10

Spray Bottle

Nitrile Gloves x 4

Print Sample

Vat Film pack sub-assembly

Vat gasket pack sub-assembly

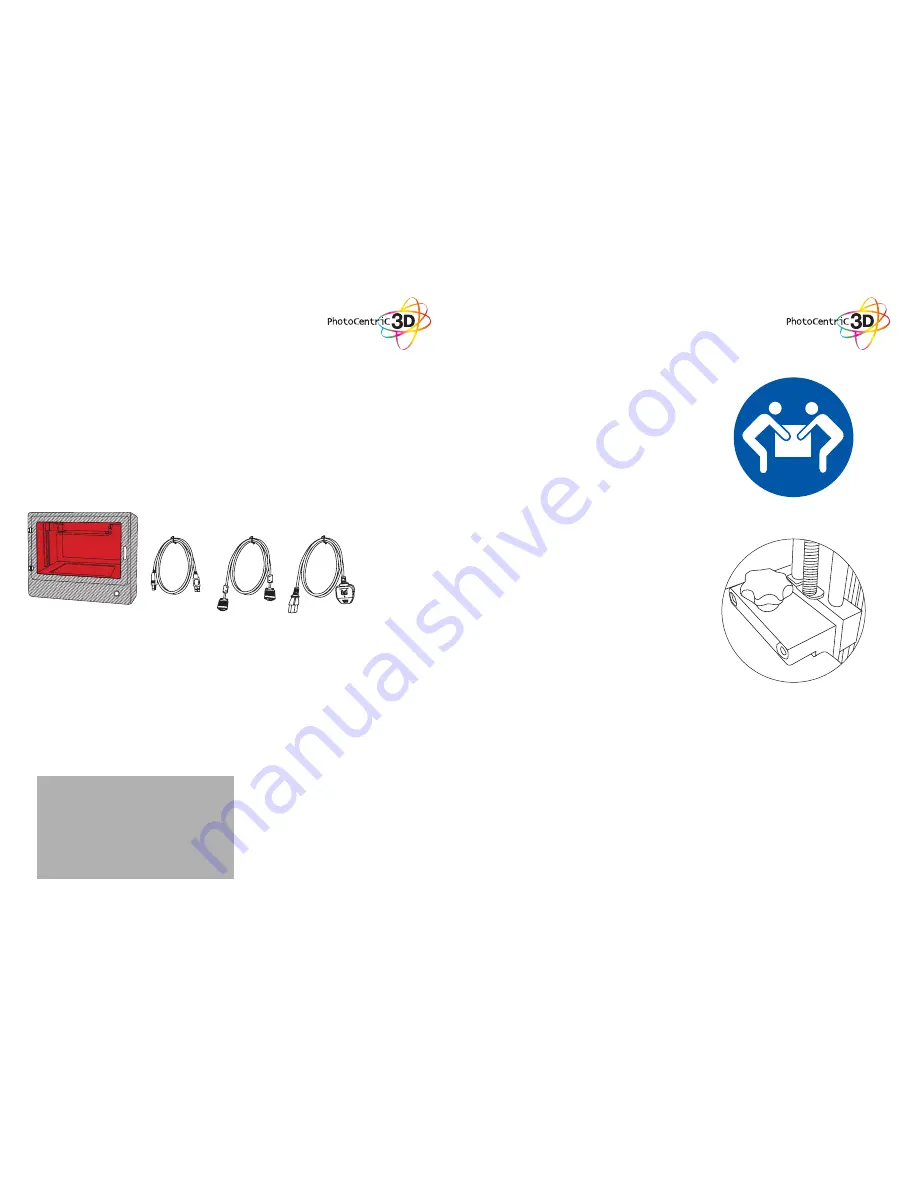

The box

contains

Liquid Crystal Pro Printer

RECOMMENDED ITEMS

• Extra gloves.

• Paper towels.

• Access to a sink with hot water to clean the

object.

• Liquid soap (detergent) to clean the object.

• Soft brush or sponge to clean the object.

• Glass or clear plastic container to post ex-

pose the object in.

• Ultrasonic Cleaner (Optional)

MINIMUM COMPUTER

REQUIREMENTS

• 1.2 GHz processor or above.

• Windows

• 2 GB RAM memory or above.

• Computer must support a UHD

monitor and have a spare display

port

1. INSTALLATION

& ASSEMBLY

INSTRUCTIONS

1. Unscrew the side panels of the crate and remove

them. The printer is heavy (approx. 65kg) so two

people are needed to lift it from the pallet and

into position.

2. Open the door and loosen the two bolts that

secure the print plate assembly to the drive

carriage.

3. Remove the whole print plate by sliding it out

towards you and set it to one side. Remove the

accessory box from inside the printer.

4. Remove the four vat bolts and carefully remove

the vat. It is quite heavy.

5. Inspect the vat for damage caused during transit

and if the film is in good condition, return it to

the printer. Do not overtighten the vat bolts!

They should lightly touch the vat and no more.

There is no need for firm pressure on the vat. If

any damage to the vat film is detected, check

for leaks by filling with water and standing on

absorbent paper for 5 minutes Then dry before

use.

ASSEMBLY INSTRUCTIONS

6

5

USB cable

Display Port

Cable

Power cable

Please keep all original packaging. In case of servicing or repairs needed, printers

must be returned fully protected.