21

There are two buttons for each of the available

options.

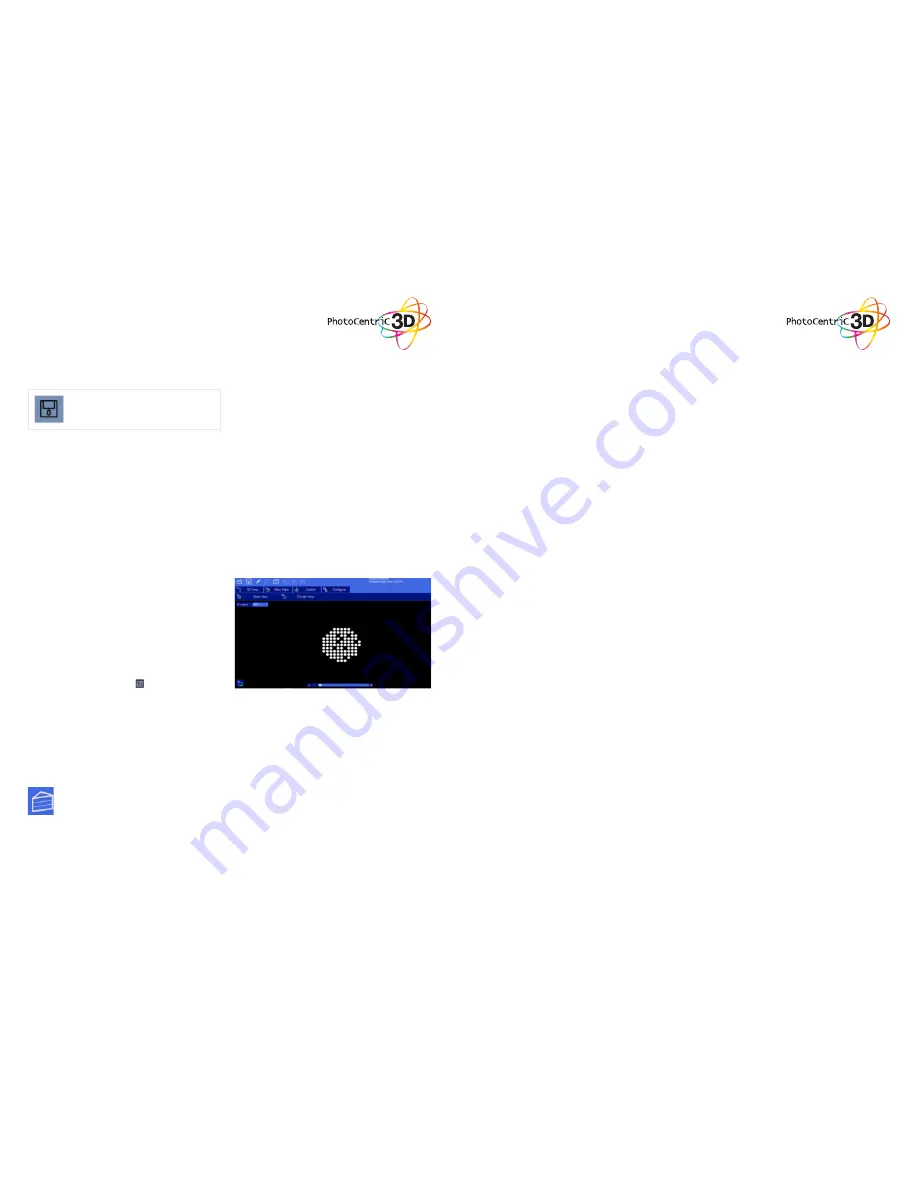

• The first option has the same name as the

screen itself (Slice View). In this setting we can

see (as shown in the image) each successive

layer of the generated “Slicing”. With the lower

bar we can scroll through the entire slicing

result to check each of the layers. In the upper

left corner we can see the total number of

layers that have been generated. In the lower

left corner we have a ( ) button to turn the

screen on and expose the selected layer.

• G-Code View: On this screen you can see

the G-code generated during the “Slicing”

operation. This option is intended for advanced

users. We recommend to leave this screen

untouched.

12. Slicing a Model

11. Slice View

In the Slice View screen we get the following

information:

After one or more models have been loaded and

manipulated on the build platform, the entire

scene can be saved as an STL model for later use.

Simply click on the ‘File->Save Scene STL’ menu

item to save the scene model. This will flatten all

models in a scene into a single STL file. Scenes

can also be saved to CWS files. These scene files

can be used to create a scene with supports,

slice the scene, and later load to print your scene

without the need for re-slicing.

Click to save the current object as a .STL or

.CWS file. The .CWS format allows you to

prepare a scene to be printed repeatedly in the

future, together with supports and positioning.

10. Saving a Scene

Once you have loaded one of the models,

configured your machine profile, and

configured your build & slicing profile, you

can slice a model. Choose the slice icon

from the toolbar ro bring up the slicing

screen.

22

You can change the currently selected slicing

profile to use. Click the ‘Slice’ button to begin

slicing. You can stop slicing by pressing

the ‘Cancel’ button. If your slicing profile is

configured to export images, a progress bar

will appear here. Otherwise, just the gcode for

the scene will be generated and the images

will be rendered during build-time.