11

12

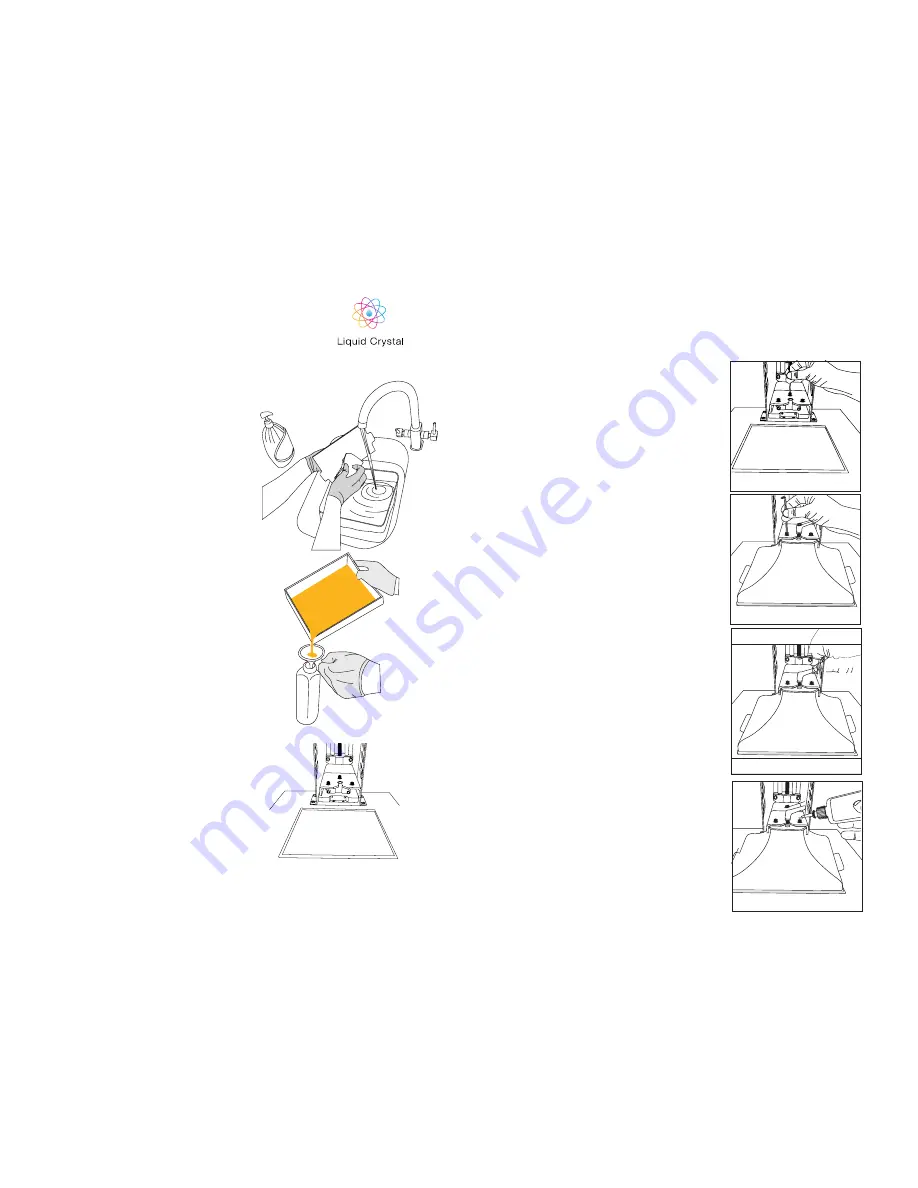

1.

Chip off any cured resin and clean the flex plate and

platform with hot water and liquid detergent. Dry it

thoroughly before inserting back into printer. Ensure

the build platform is placed on the printer with the

Serial Number sticker to the rear. Also, make sure

the flex plate is placed back on the platform with the

wings extending upwards.

2.

Empty the vat and clean it after every print in case

you have any solid pieces on the bottom as these

would prevent the platform from homing correctly.

Lift the vat from the printer; pour the resin back into

the bottle through the filter paper into the funnel

provided.

6. PREPARING FOR

THE NEXT PRINT

HR2

3

If you have a leak on the screen mop up the liquid

resin immediately using absorbent paper. Clean off

with a damp cloth with detergent. Hardened resin

can be removed by chipping off with a credit card or

plastic scraper. Metal scrapers should only be used

with extreme care to avoid scratching the screen.

4

The build platform is labelled with the Serial # of

the printer that it was supplied with. If you are using

more than one printer, it is important to ensure that

the correct build platform is placed back on the

corresponding printer. The homing of the platform is

performed during factory production, however, if re-

homing is necessary, follow the instructions below.

It is necessary to follow the homing set-up if a

new build platform is being used or if an existing

platform is to be used on a different printer. It is also,

recommended that re-homing is completed after 100

prints approximately.

5

To re-home.

With the build platform completely

removed, press the maintain button then press the

home button.

6

Loosen the three adjustment screws on top of the

print arm with an allen key.

7

Replace the build platform ensuring the Serial Number

sticker is to the rear and that the flex plate is fitted.

Do not tighten the central lever yet. Tighten each

adjustment screw until resistance is met, do not over

tighten.

8

Now tighten the central lever. Use the control panel

to raise the platform, ensuring it lifts evenly. If it does

not, repeat the homing procedure.

9

Apply locklite threadlocker to the three screws.