15709-0083 | Rev B | 2019-09-18

Entrance Below a Raised Carriage Deck | 1

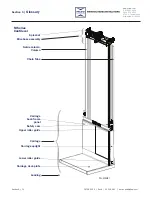

Entrance Below a

Raised Carriage Deck

www.pflow.com

P 414 352 9000

F 414 352 9002

6720 N. Teutonia Ave.

Milwaukee, WI 53209

Safety First

Minimize the

Hazards

The most common reason to access the area below a raised carriage deck is to clean

debris from the pit or hoistway. This is best accomplished using a long handled broom or

rake to avoid entry under the raised carriage deck. Entry under the raised carriage deck

is acceptable only when unavoidable and then only if the proper precautions are taken. It

is the user’s responsibility to ensure that the following conditions be met before allowing

qualified personnel to enter the area under the raised carriage deck.

z

Work must be performed by qualified maintenance technicians.

◊ ASME B20.1 defines a qualified person as “A person who, by possession of

recognized degree or certificate of professional standing or by extensive knowledge,

training, and experience, has successfully demonstrated his/her ability to solve

problems relating to the subject matter and work.”

z

The facility has performed a Risk Assessment per ASME B20.1-2015 5.16

◊

Reference OSHA 3071 for Job Hazard Analysis

◊ Reference CEMA Technical Report 2015-01, ASSE Z590.3, and MIL-STD-882 for

Risk Assessment examples.

z

A proper Lockout/Tagout (LOTO) procedure has been performed on the VRC.

◊ Refer to ANSI/ASSE Z244.1-2003 (R2014), Control of Hazardous Energy —

Lockout/Tagout and Alternative Methods, and OSHA Standard 29 CFR 1910.147,

The Control of Hazardous Energy (Lockout/Tagout).

z

At least two (2) means of support are used to secure the raised platform.

◊

The lifting systems can be used as one means of support provided that no work is

to be done on the hydraulic system or mechanical drive system and an appropriate

LOTO has been performed on the VRC.

◊ Additional means of support include adequately sized maintenance chains,

maintenance pins, DeckLocks, or straps with shackles around the drivebase that

are capable of supporting the weight of the carriage.

Every employee must be aware of the hazards before entering the area under a raised

carriage. Take appropriate steps to minimize these hazards and any others that are

identified. Some of the more common hazards are:

General

Guidelines

z

Inadequate refuge space

z

Confined space

z

Improper air quality

z

Inadequate lighting

z

Improper access

z

Tripping hazards

z

Unsafe or lack of pit ladders

z

The presence of moisture/water/oil

z

Moving equipment

z

Where a VRC is operating in a multiple

unit hoistway, that portion of the

hoistway where the work is to be

performed shall be fully separated or

accessible equipment locked out.

z

Ensure that all portable lights and

tools are connected through a Ground

Fault Circuit Interrupter (GFCI).

z

Provide adequate lighting especially if

in a shaftway.

z

For a deep pit, never “jump” into the

pit – always use a ladder.

z

Use proper hand protection while

cleaning the area beneath a raised

carriage.

z

Remove parts, lubricants, cleaning

equipment, etc from inside the pit.

z

Do not stand on the hydraulic piping or

electrical conduit.

z

Never straddle over the traveling

cable(s) if so equipped and protect it

against damage.