10

6. Maintenance

6.1. Precautionary Measures During

Maintenance Work

Whenever working on the pump ensure the

motor cannot get switched on.

If necessary, remove pump from the system for

inspection. Before dismantling allow the pump

to cool down.

➡

Only dismantle the pump as far is necessary to effect

repairs.

➡

Use only alcohol or similar cleaning agents for cleaning.

Do not use solvents.

All bearings are encapsulated and are filled with long-life

lubricant. The valves and the diaphragms are wear parts. If

the rated ultimate vacuum is no longer achieved, the pump

interior, the diaphragms and the valves must be cleaned and

the diaphragms and valves must be checked for cracks or

other damage.

Depending on individual cases it may be efficient to check

and clean the pump heads on a regular basis.

Service life of the diaphragms and valves

If the pump is operated primarily in Low-speed mode, a life of

> 12,000 operating hours can be expected.

If the pump is operated primarily in High-speed mode, a life of

> 8,000 operating hours can be expected.

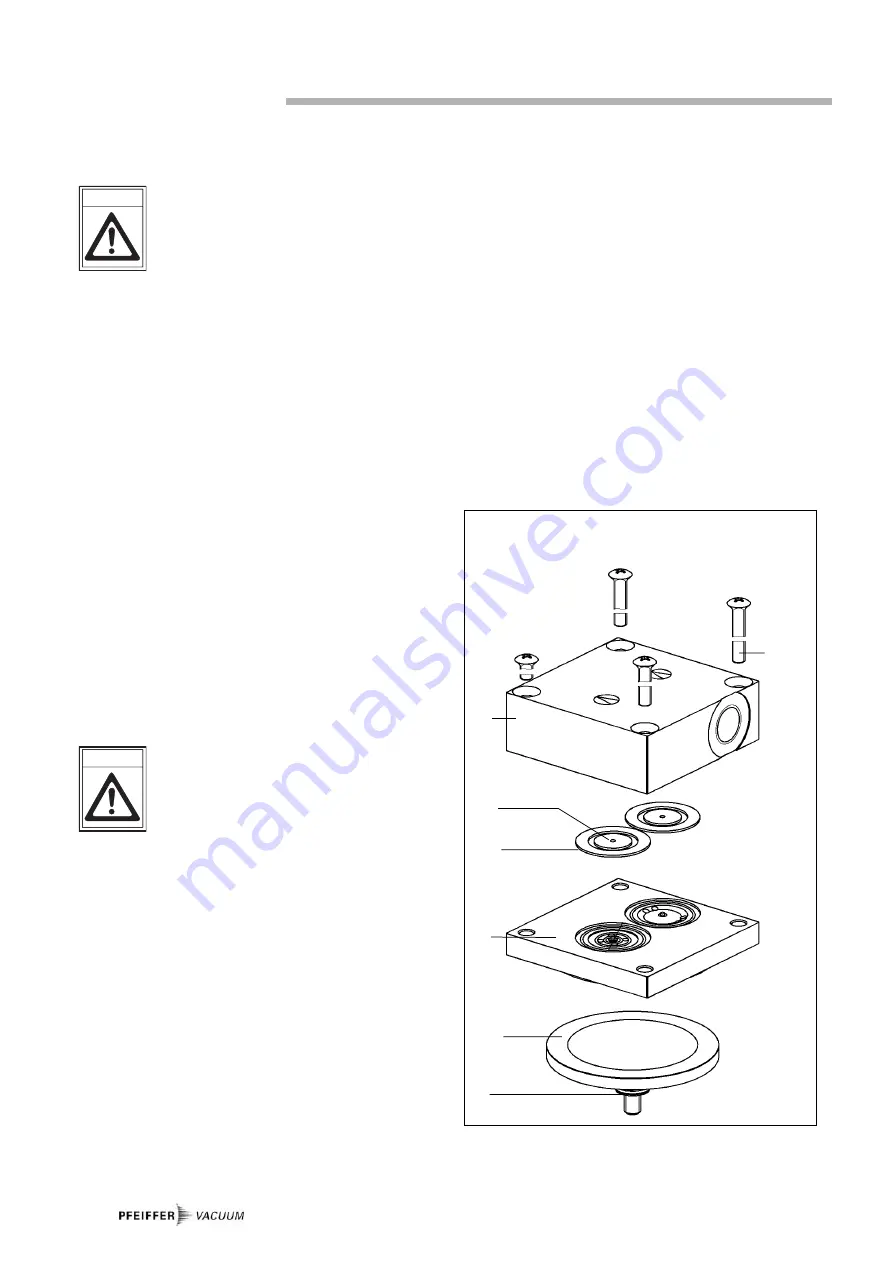

6.2. Cleaning And Replacing Valves And

Diaphram

There can be different numbers of washers 17

in each membrane head. Ensure the correct

assignment for mounting when dismantling the

membrane heads. Don’t interchange the

washers 17.

Dismantling the pump

➡

Allow the pump to cool down before dismantling.

➡

Detach intake and exhaust line from the pump.

➡

As far as possible place pump on its side so that the head

to be dismantled points up.

➡

Use open-ended wrench SW 12 to remove fitting 10.1 at

the interhead connection 10 and remove connecting hose

one-sided.

➡

Using an SW 3 key, unscrew the four crosshead screws 11

and remove head cover 12, taking care with the two valve

plates 13 and sealing rings 14.

➡

Remove intermediate plate 15.

➡

Use a small screwdriver to carefully ease out diaphragm

16 and manually unscrew from the connecting rod (right-

hand thread). Look out for possible washers 17.

CAUTION

CAUTION

Mounting the diaphragm heads

➡

All parts should be cleaned only with alcohol or similar

cleaning agents. Please check diaphragm valves and seals

for mechanical damage and replace if necessary. In case

of diaphragm change please use the existing washers 17.

If the washers are missing the pump will not reach final

pressure.

➡

Assemble all parts in reverse order. The connecting rod

should be positioned in the upper dead point when fitting

the diaphragm.

➡

Screw in diaphragm and tighten by hand.

➡

Check correct sealing ring 14 seating.

➡

Assemble membrane heads, ensure correct positioning of

all parts; mind the markings at head cover, intermediate

plate and pump housing.

➡

Re-make interhead connection 10 and re-tighten hose

fitting 10.1.

➡

Test pump for function.

12

16

17

11

Crosshead screw

12

Head cover

13

Valve plate

14

Sealing ring

15

Intermediate plate

16

Diaphragm

17

Washer

Dismantling the diaphragm heads

13

14

15

11