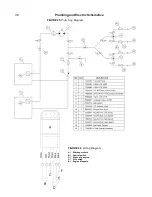

pattern in

FIGURE 18

. (4-foot when using the 30 PSI unloader

valve installed)

Adjust as follows:

Rotate the nozzle body on the pipe nipple so that the spray

pattern is pointed slightly forward.

Adjust the spray nozzle body so that the pattern width,

measured from outermost droplets to outermost droplets, is

3 FEET

(.91 meters). Increase the pattern width by

raising the nozzle level. Decrease the pattern width by

lowering the nozzle level.

Repeat the procedure for the

LOW GEAR

Trim Nozzle (

DG Tee

Jet 9503 EVS

color coded Blue). Remember to turn off the

HIGH GEAR

Spray Selector Valve. [If the Half Gallon Nozzle

Kit is installed, both Broadcast Nozzles will be used

simultaneously.]

Filling the Tanks

IMPORTANT: When filling, DO NOT add concentrated product

to an EMPTY Tank because the concentrate may be drawn into the

plumbing and sprayed through a Nozzle directly onto a lawn

causing turf damage

. Instead fill both Tanks halfway and then add

concentrate.

IMPORTANT

:

When filling, DO NOT add ALL the concentrate to

ONE Tank because the concentrate will not be evenly

distributed and sprayed through a Nozzle directly onto a lawn

causing turf damage or lack of efficacy.

There are two methods to fill the Tanks:

Method 1

: It is recommended that the Pesticide be Pre-mixed in

the proper ratio with water in a Supply Tank, and dispensed equally

as needed into the Triumph Tanks.

Remove both Tank Lids.

Add Pre-mix desired equally divided between both Tanks.

DO

NOT

overfill.

Replace both Tank Lids checking to be sure the Lid Gaskets

are in place.

Method 2

: Add Pesticide concentrate in the proper ratio with

water directly to the Tanks.

Remove both Tank Lids.

Using the Gallon marks on the rear of the Tanks calculate the

amount of fill desired for each Tank separately. Refer to

Calibration instructions in this section for additional help.

Calculate the amount of water required for each Tank.

Calculate the amount of Pesticide required for each Tank.

If the Tanks are empty or nearly so, add one half of the water

required then add Pesticide required followed by the remaining

water.

Calibrating the Sprayer

Calibrate machine ground speed to

143 FEET

in

20 SECONDS ± 1

SECOND

.

Set up a

143 FOOT

long test course. Measure a distance of

143

FEET

(44 meters) over turf.

Measure the elapsed time it takes to travel the

143 FOOT

test

course. Your elapsed time must be

20 SECONDS ± 1

SECOND

.

If your elapsed time is different:

With the machine in neutral run the engine at full throttle.

Check and adjust engine RPM to deliver an elapsed time of

20 SECONDS

(normally

3450 RPM

).

Bucket check

HIGH GEAR

Nozzle output.

With the machine in neutral and both Brakes locked, start the

engine.

Select the

HIGH GEAR

Broadcast Nozzle using the

HIGH

GEAR

Spray Selector Valve (

I

). Turn off

LOW GEAR

Spray

Selector Valve (

J

).

Place a catch receptacle in position to catch the entire spray

pattern from the Nozzle. [If the Half Gallon Nozzle Kit is

installed, approximately

ONE HALF GALLON PER THOUSAND

SQUARE FEET

is applied.]

Pull the Throttle Lever to accelerate the engine to

3450 RPM

.

Pull the spray lever to begin spraying. Spray for

1 MINUTE

,

collecting the nozzle output.

Measure the collected spray.

[If the Half Gallon Nozzle Kit is installed, approximately

ONE

HALF GALLON PER THOUSAND SQUARE FEET

(1.9 L ±

0.95 milliliters) is applied.]

Correctly align

ALL

Nozzles. Refer to Adjusting Nozzles for

proper spray pattern in this section.

Locking in the Nozzle Position

Once the machine is properly calibrated, the angle of the nozzle

bodies can be locked with the user installed Nozzle Stop Kit

(shipped in the Parts Bag in the Hopper). If the nozzle body is

moved, you will instantly be able to return it to the proper position

contacting the bolt.

Insert bolt (A) through the slots in the nozzle mounting plates.

Tighten lock washer and nut so the bolt touches the front side of

the nozzle cap. Add Protective cap. Repeat the process for each

nozzle body.

Calculating the Spray Mix Rate

Sprayer Operation and Calibration

27

Nozzle

20 PSI

7-Foot turns

30 PSI

8-Foot turns

High gear Broadcast

TF-VS7.5-90, green

96 oz.

112 oz.

Low gear Broadcast

TF-VS4-90, white

76 oz.

86 oz.

High gear Trim

DG

9504, red

34 oz.

44 oz.

Low gear Trim

DG

9503, blue

26 oz.

34 oz.

Output from the Nozzles must be plus or minus 15%

.

If the output from a nozzle is significantly outside the limits,

refer to

SECTION 4

, Troubleshooting.

A

FIGURE 18

, Trim spray pattern

6

foot