1

IntelliFlo VS+ SVRS Installation and User’s Guide

Section 1

IntelliFlo VS+ SVRS Overview

IntelliFlo

®

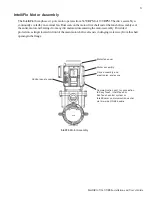

VS+ SVRS Variable Speed Pump

The IntelliFlo VS+ SVRS variable speed pump with the safety vacuum release system (SVRS) protection is

well suited for all of your pool, spa, waterfall and other applications. The IntelliFlo VS+ SVRS can use up

to eight (8) speeds which can be adjusted to run at specific speeds and time intervals. IntelliFlo out

performs all conventional pumps in its class. Advanced energy conservation features ensure that your

filtration system is operating at peak efficiency.

The IntelliFlo pump operates at a maximum system flow rate of up to 174 gallons per minute (GPM).

System setup for the SVRS requires that the suction vacuum level be adjusted to 25" of mercury (Hg) or

less at the pump strainer housing connection.

The IntelliFlo VS+ SVRS pump can operate from 1100 RPM to 3450 RPM with preset speeds of 1100,

1500, 2350 and 3110 RPM. The pump can be adjusted from the control panel to run at any speed

between 1100 RPM to 3450 RPM for different applications. The IntelliFlo pump control panel alarm LED

and error messages warn the user against under and over voltage, high temperature, over current, suction

blockage and freeze protection with user defined minimum and maximum speed presets. See page 39 for

additional information.

This pump is intended to be used as part of a complete pool safety system. It complies with the ASME/

ANSI A112.19.17-2002 SVRS standard which defines how fast the pump must stop on a suction blockage

event. This pump may not protect individuals from hair entrapment, limb entrapment or evisceration. The

operator must ensure that all suction and return fittings are clean and unobstructed whenever the pump is

started.

Because SVRS protection is not enabled during priming mode, never allow anyone in the

pool during priming mode.

If SVRS auto restart is enabled and an SVRS event occurs, the pump is allowed to restart automatically

after the preset time period.

The operator must insure that any SVRS blockage event is quickly

evaluated to confirm that all suction and return fittings are clean and unobstructed.

When the pump

restarts after a high vacuum event it will slowly ramp up to speed. If the pump senses a blockage it will shut

down. The pump will attempt to soft prime 10 times before attempting a full prime.

Remote Control

The IntelliFlo VS+ SVRS can communicate with an

IntelliTouch

®

, EasyTouch

®

, or SunTouch

®

control system or the

IntelliComm

®

communication center via a two-wire RS-485

cable provided with the pump. EasyTouch and IntelliComm

can remotely control the IntelliFlo VS+ SVRS four preset

speeds. The IntelliTouch system can be configured to control a

total of eight speeds. The pump’s address and other pump

functions are accessed from the pump’s control panel.

IntelliFlo VS+ SVRS Variable Speed Pump