11

SHURflo Operating Instructions, Performance,

Specifications and Parts Manual

Viton Models GMSV2A, GMSV4A, GMSV6C, GMSV2A3T, GMSV2A33T,

GMSV4A5T, GMSV4A53T, GMSV6C7T and GMSV6C73T

Teflon

®

Models GMST2A, GMST4A, GMST6C, GMST2A3T, GMST2A33T,

GMST4A5T, GMST4A53T, GMST6C7T and GMST6C73T

Form L-4089 (2/17)

Step 1: Select a T pipe coupling that is

consistent with discharge pipe size and

material. Couple to discharge piping.

Step 2: From this coupling, attach a

needle valve with appropriate nipple,

reducing to 1/8” pipe or tube. Install

appropriate flow meter.

Step 3: Connect 1/8” pipe or tube to

one of three available seal cavity flush

ports.

Step 4: Adjust needle valve to desired

flow into seal cavity (recommended

1 to 3 GPH).

For alternate flush

systems for hazardous

fluid applications, hot

liquid transfer, and those not addressed in

this booklet, consult a qualified fluid han-

dling specialist for

assistance in specifying and installing flush

systems according to local, state and federal

environmental laws.

GEAR SPEED REDUCER OPTIONS

A gear reducer can be directly mounted

between a standard pump and motor

combination. Gear speed reducers are

available for applications with high

specific gravity, or when viscosities are

greater than 500 SSU, using a standard

1725 RPM motor (See Appendix 2). The

pump relationship between volume

(GPM), pressure (PSI), speed (RPM),

viscosity, specific gravity and horsepow-

er is shown on performance chart in

Shurflo Motor Manual form L-4082.

8. Unit is ready for operation.

Maintenance

Make certain that the

power source is

disconnected before

attempting to service

or disassemble any components!

If the power disconnect is out of sight, lock

it in the open position and tag to prevent

application of power.

CLEANING

Clean the suction line filter at regular

intervals.

ELECTRIC MOTOR

Properly selected and installed, elec-

tric motors are capable of operating

for years with minimal maintenance.

Periodically clean dirt accumulations

from open-type motors, especially in

and around vent openings, preferably

by vacuuming (avoid imbedding dirt in

windings). Oil and maintain as recom-

mended by motor manufacturer.

GENERAL

Check the pump to motor shaft coupler

alignment at regular intervals.

Periodically check that electrical connec-

tions are tight. Pump should be drained

if placed in an area that is subject to

freezing temperatures and should not

be operated until temperature permits.

To store the pump, place a small quan-

tity of light oil or some other storage

preservative compatible with your appli-

cation in the pump and rotate the shaft

very slowly to work the oil throughout

the gears and the body.

PUMP REPAIR

DISASSEMBLY

(Refer to Figure 13 for Reference

Numbers and Figures 3, 8, 9, 10, 11 & 12

for detailed seal and shaft assemblies.)

1. Remove pump from motor.

a. Remove the coupler half from the

pump (See Figure 3). The motor

coupler half does not need to be

removed unless motor is being

replaced.

2. Gear Removal

a. Remove cover plate (Ref. No. 2)

(held by eight screws) and gasket

(Ref. No. 3) if needed. Gently tap

cover plate with rubber mallet

to free it from dowel pins. Once

cover is removed, the idler shaft

and gear assembly can be pulled

out of pump body (Ref. No. 12).

b. Remove the idler gear (Ref. No.

6) from the shaft (Ref. No. 7) by

removing retaining rings (Ref.

No. 5), then slide gears off the

shaft end.

c. The drive gear (Ref. No. 6) can

be pulled out. Before drive shaft

(Ref. No. 9) can be removed

from body (Ref. No. 12), remove

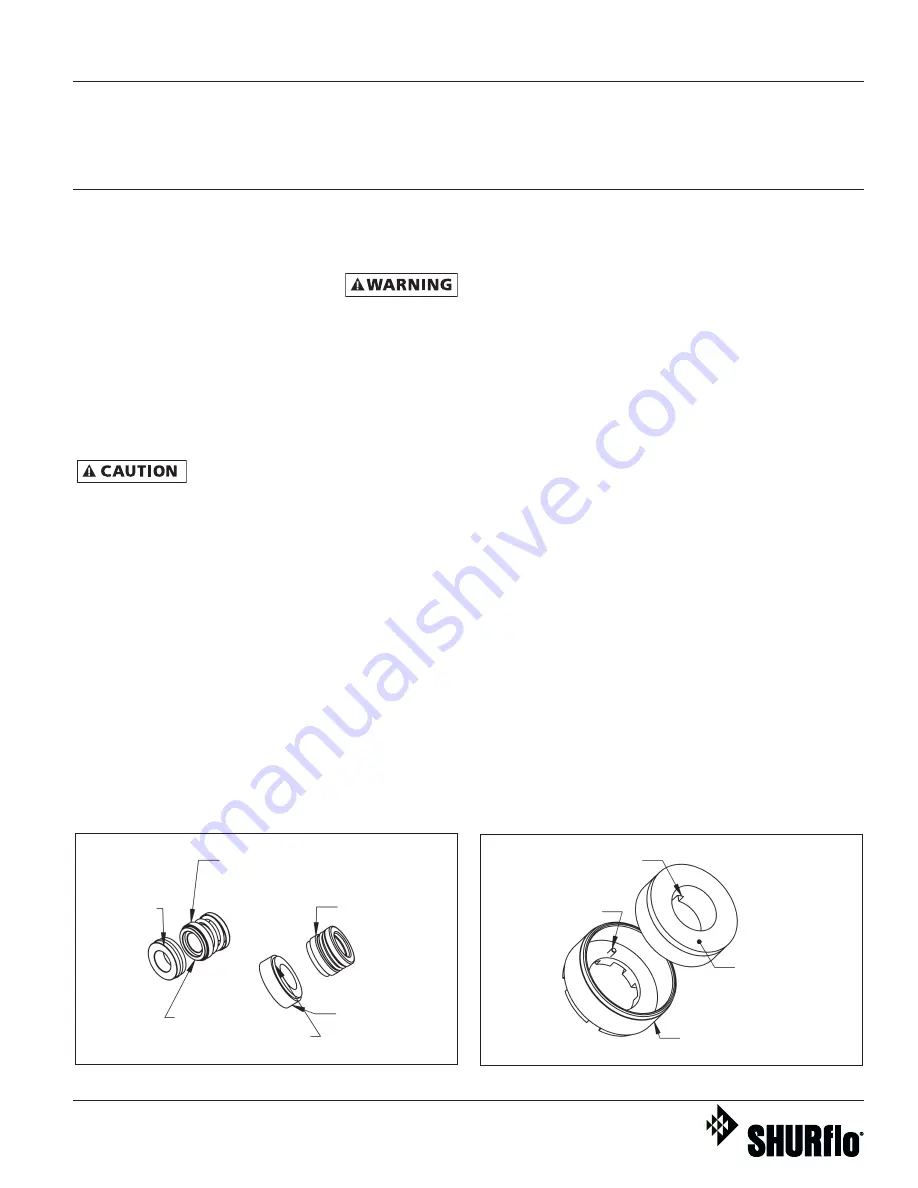

Figure 10 - Seal Types and Parts Identification

Figure 11 - Seal Seat and Retainer Assembly

Mechanical Seal with

Seal, Spring & Retainer

(three loose pieces)

One-piece

Mechanical Seal

with Thru Boot

Ceramic Seat

with Rubber Cup

Seal Seat

(Ref. 14)

Notch in seat

aligned with pin

Anti-Rotation

Spring Pin

(Teflon Seals Only)

Seat Retainer

(Ref. 15)

Ceramic Seat

with O-ring

Polished Face

always goes against

Carbon Face of seal