1020 FMD

22

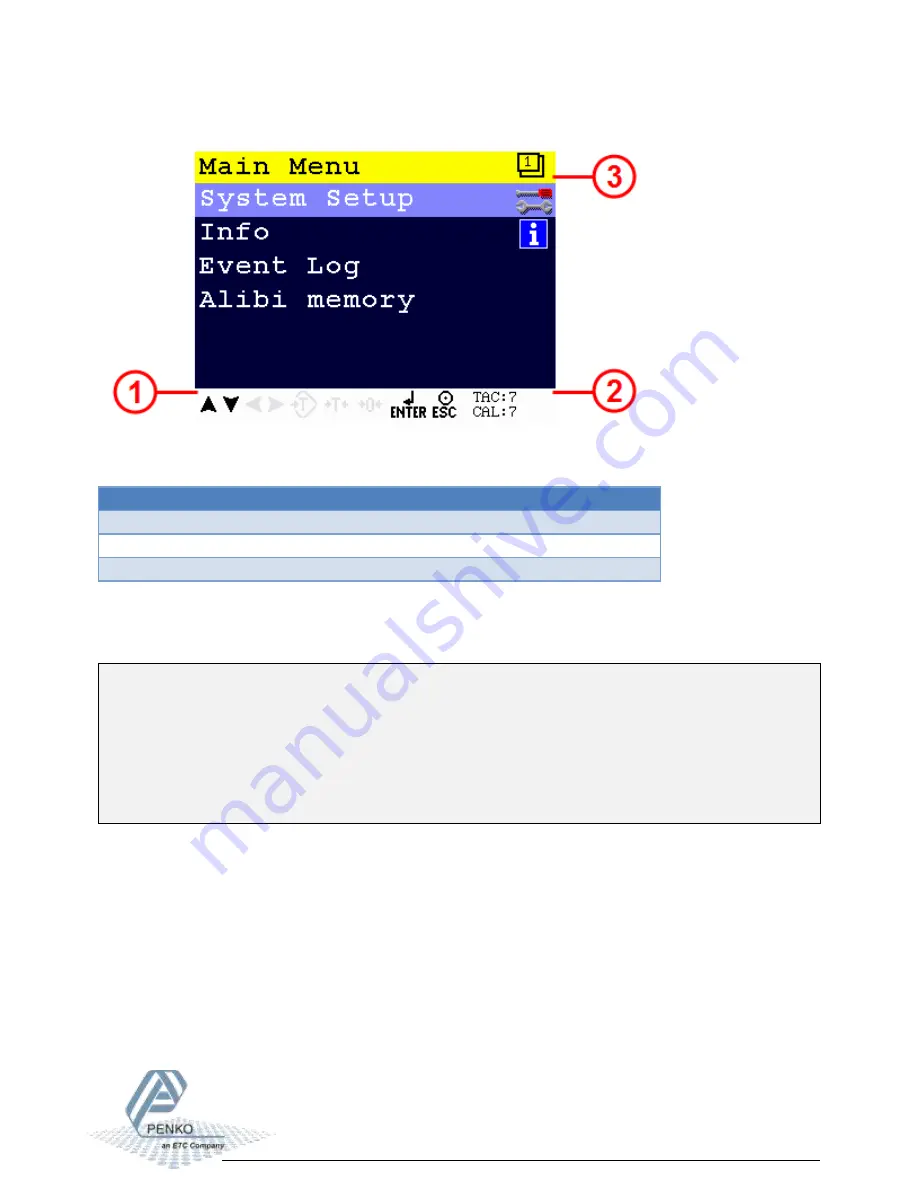

The display indications in menu mode:

Number

Description

1

Active buttons for current menu item

2

TAC and CAL code*

3

Menu level

* TAC and CAL code

TAC

stands for Traceable Access Code. A number of settings are only available after entering

this code. When these settings are changed, the TAC is incremented with 1.

CAL

stands for CALibration code. The calibration settings are only available after entering this

code. When the calibration settings are changed, the CAL is incremented with 1.

Summary of Contents for 1020 FMD

Page 7: ...1020 FMD 7 1 Overview Option 1 Option 2...

Page 19: ...1020 FMD 19 RS232 communication RS422 communication with multiple devices...

Page 21: ...1020 FMD 21 Hold function Peak Valley and T I R function...

Page 99: ...1020 FMD 99...

Page 103: ...1020 FMD 103...

Page 106: ...1020 FMD 106 Appendix I Menu structure...

Page 107: ...1020 FMD 107...

Page 108: ...1020 FMD 108...