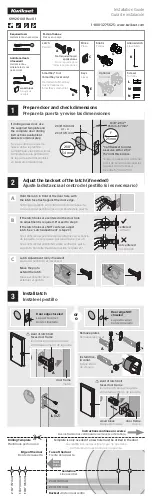

Sill Pan

Sill Nose

#1

#2

Sill Nose

2

OPENING PREPARATION (CONTINUED)

O.

Cut two pieces of flashing

tape

12" longer than the

rough opening width. Place

tape #1 across the sill nosing

just up to where the nosing

begins to slope down and

extending 6" up each jamb.

Apply the second piece of

flashing tape over-lapping

the first piece and the exterior

edge of the sill pan and 6" up

each jamb.

3

PREPARE THE DOOR FOR INSTALLATION

TWO OR MORE PEOPLE WILL BE REQUIRED TO HANDLE THE PANEL AND FRAME SAFELY.

A.

Remove the plastic wrap and cardboard packaging from the door.

Note: If screens, grilles or hardware are removed from the door at this time, label them

and store them in a protected area.

B.

Remove the shipping spacers.

Carefully slide the movable panel halfway open and

remove the spacers from both the top and bottom of the movable panel.

C.

Remove the venting panel

by lifting it off of the lower track and tilting the bottom of the

panel away from the door frame. Then, lower the panel out of the top track. Carefully set

the panel aside.

D.

Drill 13/64" diameter clearance holes

through the frame at a 45° angle, on the room side

of the door lock jamb and fixed jamb in the locations shown. Space the holes a maximum

of 6" from each end and a maximum of 10" on center.

6" MAX

6" MAX

10" MAX

10" MAX

10" MAX

10" MAX

10" MAX

10" MAX

10" MAX

FIXED JAMB

VENT JAMB

EXTERIOR

INTERIOR

Drill 13/64" clearance holes

through frame at 45° angle

2D

3D

SILL TAPES

2O

E.

Drill a 13/64" clearance hole through the door

frame

at each indentation in the extrusion at the

top (head) of the door frame.

2O