8

2-4 Belt Installation

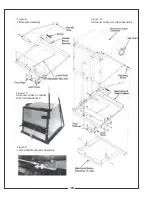

Loosen the (4) bolts P#(K1191), (2) on each side, that

secure the gear box assembly to the PTO assembly

P#(A0623) (Figure 2-4a). Loosen the adjustment bolt

P#(K0348) until the gear box assembly is at its far left

adjustment (the gear box is moved toward the mower’s

engine pulley). Connect the A63K kevlar cord belt

P#(M0252) from the engine pulley to the lower gear box

pulley (Figure 2-4b). To tension the drive belt, turn the

adjustment bolt clockwise until there is 1” of deflection,

with 10-11 lbs. of pressure, at the center of the belt

between the engine pulley and the gear box pulley. Once

the correct tension of the belt is achieved, tighten the (4)

bolts that secure the gear box assembly.

Gear Box Assembly

Adjustment Bolt

Loosen These

(4) Bolts

Engine Pulley

Figure 2-4a.

Figure 2-4b.

Top Main Frame

Assembly

(2) 3/8” -16 x 1-1/4” HHCS

(2) 3/8”-16 Flange Nuts

Per Side

2-5 Cam Assembly Adjustment

The cam assembly P#(A0422), which controls the

blower belt tension, comes from the factory pre-adjusted.

If the belt is too tight or becomes too loose, remove the

hair pin clip P#(K0099) from the belt tension rod

P#(K0326) and pull the “L” end of the rod out of it’s hole

in the cam assembly. The tension rod may then be

screwed out to tighten the belt or screwed in to loosen

the belt. Replace the “L” end into the top hole in the cam

and replace the hair pin clip. Adjust the cam stop bolt

P#(K1159) to allow the cam to rotate slightly over center

when the blower is disengaged (Figure 2-5).

2-6 Top Main Frame Assembly

Installaton

Place the top main frame assembly P#(A0618) (Fig. 2-2)

onto the main frame legs and fasten each side by using

(2) 3/8”-16 x 1-1/4” HHCS P#(K0309) and (2) 3/8”-16

flange nuts P#(K1215).

Cam Assy.

Tension Rod

Figure 2-5.

Cam Stop

Bolt

Summary of Contents for 50721201

Page 14: ...PTO Parts List 14...

Page 21: ...21...