Page 69

Ph: 804.227.3023

10511 Old Ridge Rd. Ashland, VA 23005

4LHD/4LHDX Application Manual

Powertrain Control Solutions

REV 1.1

TPS Verification Checklist

You must be able to answer YES to all of these statements to verify proper sensor installation.

1. The sensor is mounted in a location that is free from excessive vibration, protected from heat sources,

debris, and fluids.

2. The sensor is mounted with proper fasteners (lock washers, lock nuts, etc) and uses appropriate

materials (no uncoated steel, etc) for the sensor to last the anticipated life of the vehicle.

3. When the accelerator pedal is at idle (not depressed), the sensor arm is off of the minimum stop and

the voltage as shown on the TCM software monitor screen is between 0.5V and 1.5V.

4. When the sensor arm is disconnected from the linkage that connects it to the engine or pedal, the

sensor arm returns to the minimum stop and the voltage on the TCM software monitor screen is below 0.2V. Code 22

becomes active after three seconds.

5. When the pedal is pressed, the sensor arm moves accordingly. There is no movement or “slop” such

that the pedal or engine throttle blade can move without seeing a voltage change on the TCM software monitor screen.

6. The sensor moves freely without binding. The sensor does not provide any resistance or change to

the operation of the throttle linkage.

7. When the accelerator pedal is at full throttle, the sensor arm does not contact the maximum stop and

the voltage as shown on the TCM software monitor screen is between 3.5V and 4.5V.

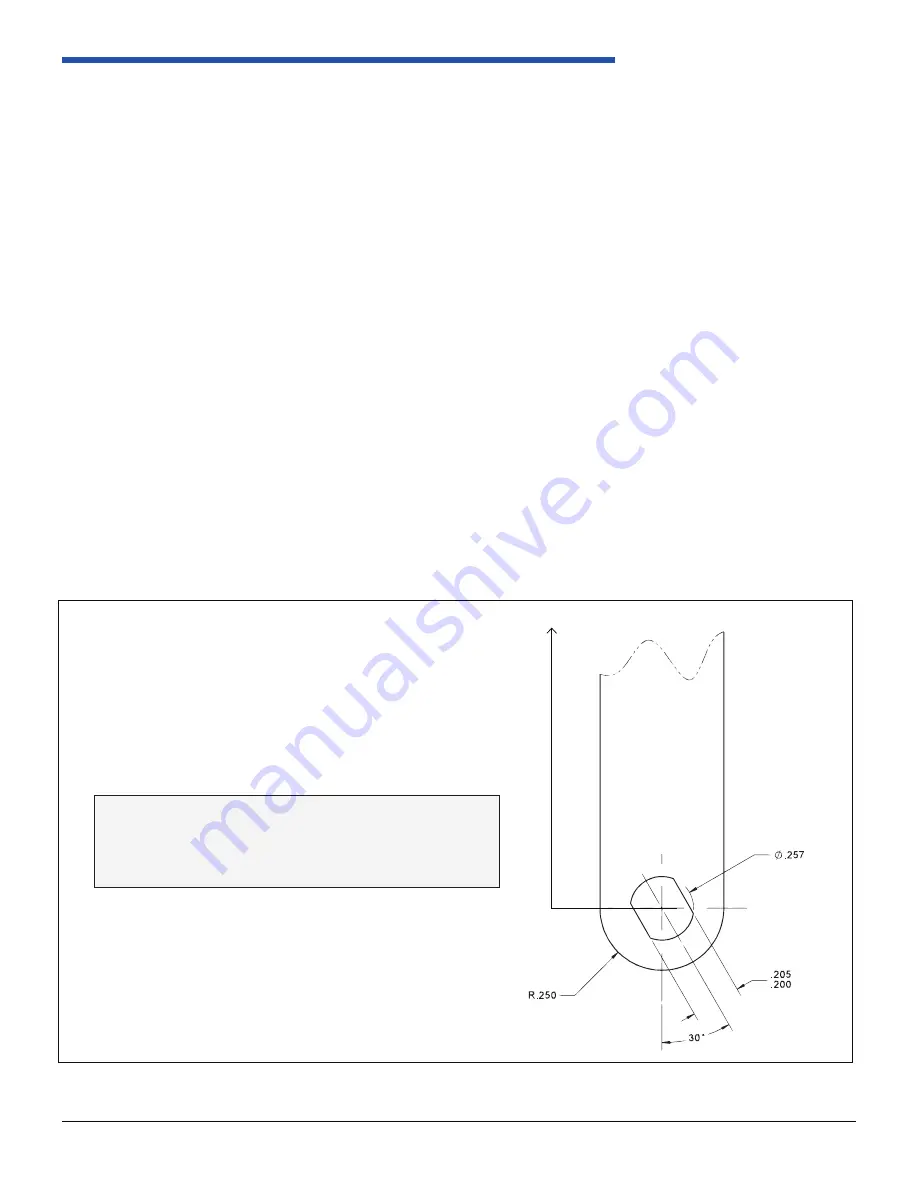

It is strongly recommended to use the arm provided by

PCS. In situations where the vehicle manufacturer must

design a custom arm, refer to figure 2.6.8.12-3 provided

for the design of the arm to the sensor.

Minimum length: 1.5” (so arm contacts stops)

Figure 2.6-3: Shift Arm Specifications