Manual

7

6

Operation

6.1

Preparations before the measurement

6.1.1

Sample

Type of hydraulic impactor

Classification of samples in weight classes

Heavy

Medium-weight

Light

D

>5 kg

2 … 5 kg

0,05 … 2 kg

Please note that the hydraulic impactor is shortly subjected to a relatively high impact force, considering

his low mass and his impact energy, when it impinges on the surface. The maximum impact force for a

type D device is 900 Newton.

-

The surface temperature of the test object should be below 120 °C.

-

The test object should obtain a smoothly grinded surface in order to avoid faulty measurements.

These faulty measurements may be an effect of rough grinding or grooves by a lath machine.

-

The throatiness of the test object shall not exceed 2 µm.

-

For test object above 5 kg, which have a compact form, there are no preparations needed,

-

Test objects between 2 and 5 kg or heavier objects with protruding parts or thin sides shall be

placed on a stable subsurface so they do not break or deform when the hydraulic impactor hits

them. If they deform or break the Leeb value may be wrong.

-

Note that also bigger test objects may deform if they have thin sides or protruding parts.

-

Test objects below 2 kg should be coupled to a stable (above 5 kg heavy) subsurface.

-

The hardened layer of the testing object no not be any thinner than 0,8 mm.

-

The surface of the test object should not be magnetic.

-

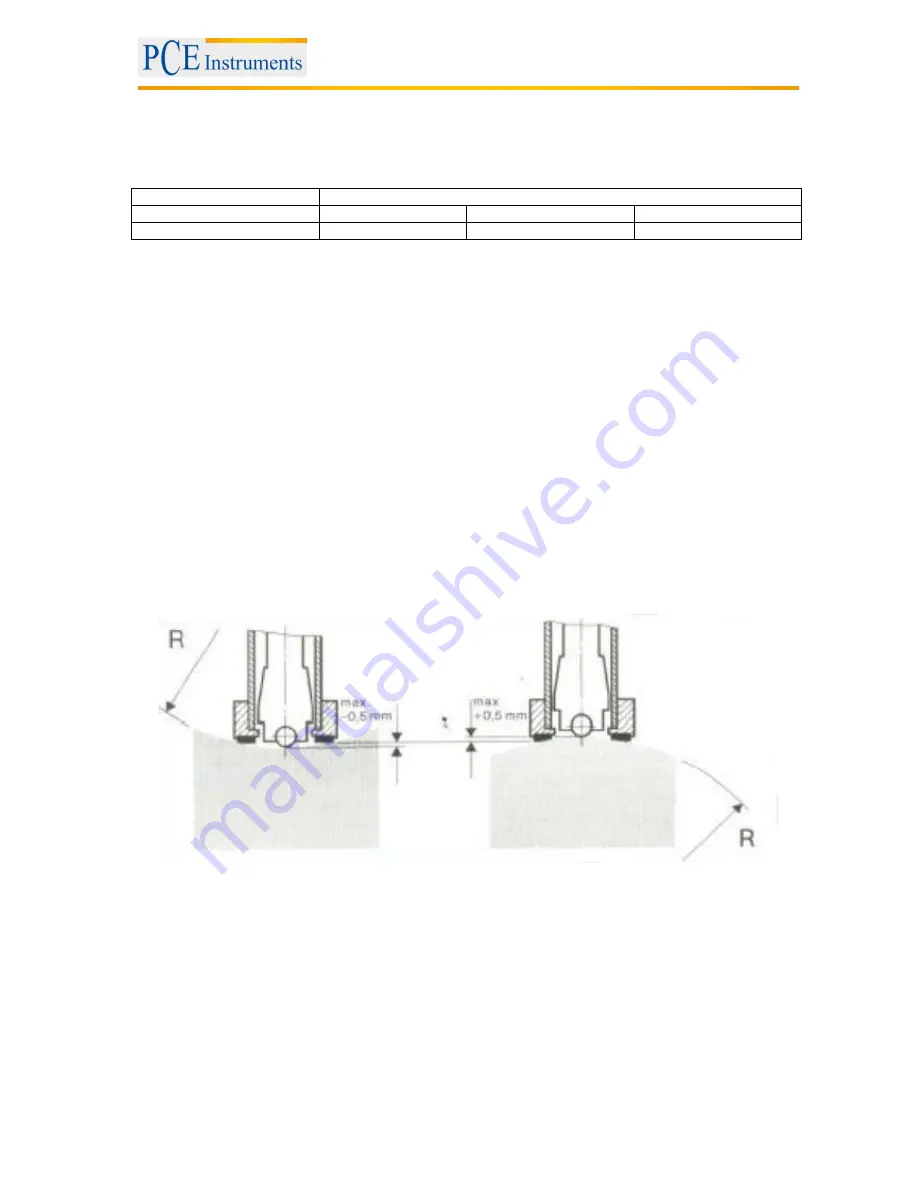

Curved surfaces of test objects should at least have a radius 30 mm. Otherwise a supporting ring

is needed.

-

Measuring instruments that work by using the impact force only work properly when the impactor

is at a certain point of the guide tube, when hitting the test object. If spherical or cylindrical

objects that are arched to the inside of the test object are measured, the measurement may not

be correct.