33

Additional Propane Connection

Requirements

1. Have a licensed Propane gas dealer make all connections

at storage tank and check all connections from tank to fur-

nace.

2. If copper tubing is used, it

MUST

comply with limitation

set in National Fuel Gas Code or CGA codes.

3. Two--stage regulation of Propane gas is recommended.

Propane Conversion

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal injury or

death.

A Propane conversion accessory kit is required when

operating the furnace with Propane gas.

!

WARNING

An accessory kit shall be used to convert to propane gas use, see

the furnace rating plate for the Propane conversion accessory kit

part number.

Supply Pressure

FIRE HAZARD

Failure to follow this warning could result in personal injury or

death.

Do NOT set input rating above that shown on rating plate.

!

WARNING

1. A

1

/

8

″

NPT plugged tapping, accessible for a test gauge

connection, must be installed immediately upstream of the

gas supply connection to the furnace.

2. Gas input to burners

MUST NOT

exceed the rated input

shown on rating plate.

3. Do

NOT

allow minimum gas supply pressure to vary

downward. Doing so will decrease input to furnace. Refer

to Table 6 and Table 7 for normal gas supply and manifold

pressures.

Manifold Gas Pressure Adjustment

SEE CHECKS AND ADJUSTMENTS, Manifold Gas

Pressure Adjustment

in this manual.

ON

OFF

ON

O

FF

O

N

O

F

F

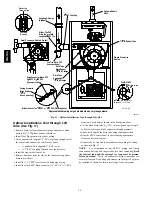

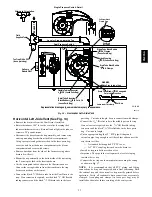

Use elbows and 3

″

pipe nipple to connect valve to

piping when using right side gas pipe entry.

* Union may be installed inside the cabinet when necessary

because of clearances.

Drip Leg and Union, Union* should be outside the

cabinet. Manual shut- off valve MUST be upstream of

dripleg, union, and furnace.

Propane Low pres-

sure switch

REQUIRED.

Vent Pipe Grommet (Single Pipe)

3

″

pipe

nipple

Models may

have 1 or 2

pressure

switches

Manual shut- off

valve

Alternative

installation

Representative drawing only, some models may vary in appearance.

A07724

Fig. 34 -- Typical Gas Piping for Upflow

PG9Y

AA