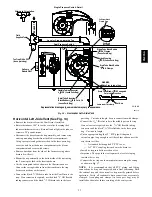

10

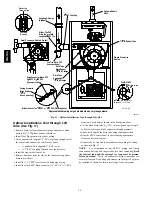

Minimum One Inlet and One Outlet Air Supply is Required

May be in any Combination Shown

Inlet Air Opening Must be Within12

″

of floor

Outlet Air Opening Must be Within12

″

of ceiling

(1) 1 Square Inch per 4000 BTUH

(2) 1 Square Inch per 2000 BTUH

This installation NOT approved in Canada

Gas Vent

Gable Vent

Ventilated Attic

Top Above Insulation

Alternate Inlet Air (1)

Ventilated Crawl Space

Outlet Air (1)

Soffit Vent

Outlet

Air (1)

Inlet

Air (1)

Outlet

Air (2)

Inlet

Air (2)

Gas Vent

Inlet

Air (2)

Soffit Vent

Gas Vent

Gable Vent

Ventilated Attic

Top Above Insulation

Inlet

Air (1)

OutletAir (1)

alternate Inlet Air (1)

A07704

Fig. 5 -- Outside Air

(This is ONLY a guide. Subject to codes of country having jurisdiction).

This furnace

MUST NOT

be installed directly on carpeting or

tile or other combustible material other than wood flooring or

supports.

For horizontal installation over a finished living space. A field

fabricated auxiliary drain pan with drain pipe is required to

prevent damage by overflow due to blocked condensate drain.

COMBUSTION & VENTILATION AIR

For Single Pipe Installation

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or

death.

Use methods described here to provide combustion and

ventilation air.

!

WARNING

Furnaces require ventilation openings to provide sufficient air for

proper combustion and ventilation of flue gases. All duct or

openings for supplying combustion and ventilation air must

comply with the gas codes, or in the absence of local codes, the

applicable national codes.

Combustion and ventilation air must be supplied in accordance

with one of the following:

NOTE

:

The Combustion & Ventilation Air Section in this

document, uses tables and information from the ANSI

Z223.1/NFPA 54. For use in Canada, use CSA B149.1 for this

information.

1. Section 9.3, Air for Combustion and Ventilation, of the

National

Fuel

Gas

Code,

(NFGC),

ANSI

Z223.1--2006/NFPA 54--2006 in the U.S.,

2. Sections 8.2, 8.3, 8.5, 8.6, 8.7, and 8.8 of National Stand-

ard of Canada, Natural Gas and Propane Installation Code

(NSCNGPIC), CSA B149.1--05 in Canada,

3. Applicable provisions of the local building code.

This furnace can NOT be common vented or connected to any

type B, BW or L vent or vent connector, nor to any portion of a

factory--built or masonry chimney. Multistory venting is NOT

permitted.

If

this

furnace

is

replacing

a

previously

common-vented furnace, it may be necessary to resize the

existing vent and chimney to prevent oversizing problems for the

other remaining appliance(s). See

“Venting and Combustion Air

Check”

in this section

.

This furnace MUST be vented to the

outside.

When the installation is complete, check that all appliances have

adequate combustion air and are venting properly. See

Venting

And Combustion Air Check

in “

Gas Vent Installation”

Section in

this manual.

Outdoor Combustion Air Method

A space having less than 50 cubic feet per 1,000 BTUH input

rating for all gas appliances installed in the space requires

outdoor air for combustion and ventilation.

Air Openings and Connecting Ducts

1. Total input rating for all gas appliances in the space

MUST

be considered when determining free area of open-

ings.

2. Connect ducts or openings directly to the outdoors.

3. When screens are used to cover openings, the openings

MUST

be no smaller than

1

/

4

″

(6.35 mm) mesh.

4. The minimum dimension of air ducts

MUST NOT

be less

than 3

″

.

5. When sizing a grille, louver, or screen use the free area of

opening. If free area is

NOT

stamped or marked on grill or

louver, assume a 20% free area for wood and 60% for met-

al. Screens shall have a mesh size not smaller than

1

/

4

″

(6.35 mm) .

Confined Space Installation

NOTE

: A confined space is defined as an area with less than 50

cubic feet per 1,000 BTUH input rating for all gas appliances

installed in the area.

Requirements

1. Provide the space with sufficient air for proper combustion

and ventilation of flue gases using horizontal or vertical

ducts or openings.

PG9Y

AA