3.2 DETAILED SWITCH SETTINGS

This section provides detailed information about the function of

each DIP switch and lists all possible settings.

Switch 1: Hardware/Software Control

The setting for Switch 1 determines whether these interface

converters will control either hardware or software flow control.

Switch 2: Enable/Disable LED Indicator

The setting for Switch 2 determines whether the LED indicator is

enabled or disabled.

5

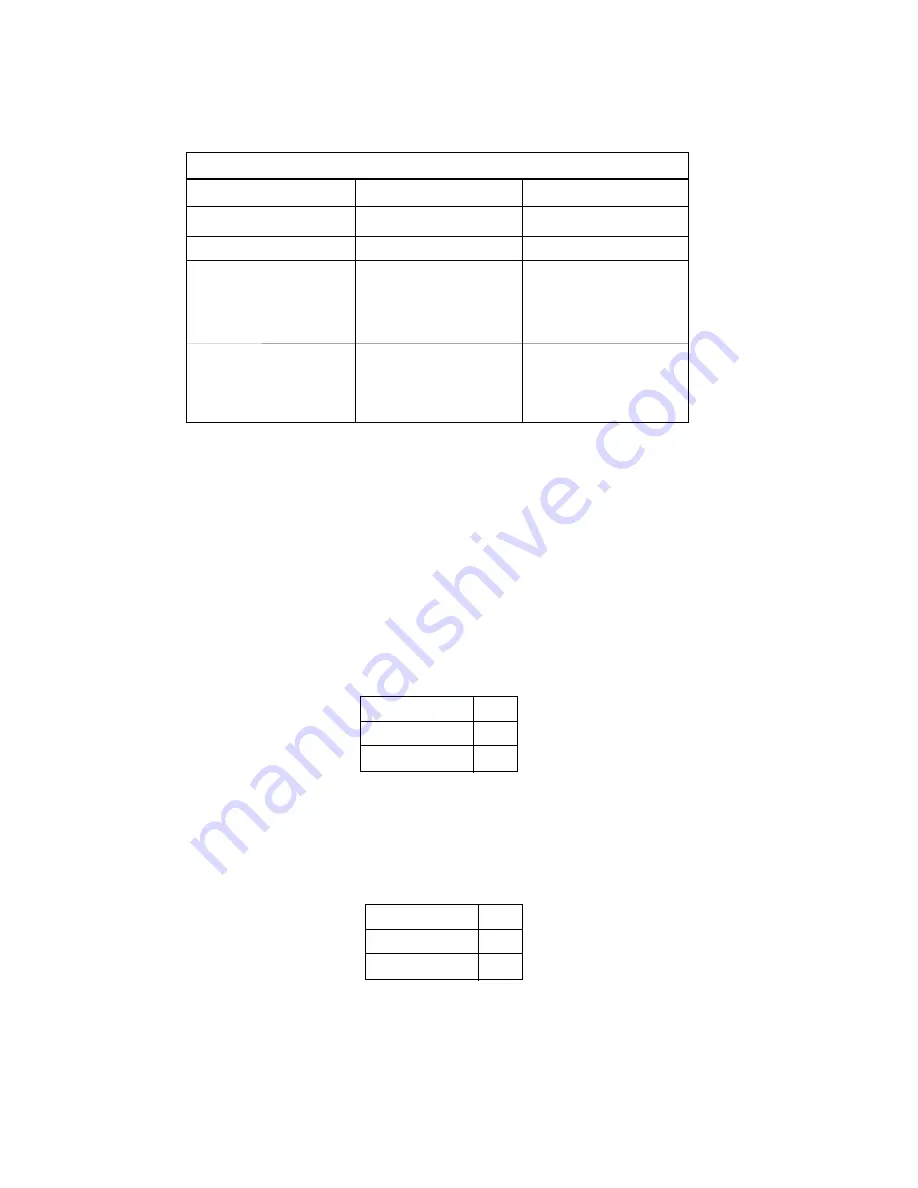

Flow Control SW1

Hardware

OFF

Software

ON

LED

SW2

Enabled

ON

Disabled

OFF

DIP SWITCH SUMMARY TABLE

Position

Function

Factory Default

SW1

Flow Control

Off

SW2

LED Indicator

On

SW3

Data, Parity, Stop Bits

Off

SW4

Data, Parity, Stop Bits

Off

SW5

Data, Parity, Stop Bits

Off

SW6

Data Rate

Off

SW7

Data Rate

Off

SW8

Data Rate

Off

Hardware

Enabled

8B, NP, 1S

38400 bps

}

}

5.0 OPERATION

Once your interface converter is properly configured and installed,

it should operate transparently—as if it were a standard cable

connection. Operating power is derived from the RS-232 data and

control signals; there is no “ON/OFF” switch.

5.1 LED STATUS MONITORS

The Model 2036 and 2037 feature an easy-to-read LED that shows

the operating status of the Model 2036. Figure 1 (page 4) shows the

location of these LEDs. The following chart describes the LED’s status

codes.

Please refer to the following key to interpret the above status

codes:

8

LED Codes

● ●

—

●

———

● ●

—

●

———

Computer is sending data

●

———

●

———

●

———

Serial device is connected; computer is

not sending data

● ●

———

● ●

———

Both serial and parallel devices are

connected; computer not sending data

●

—

●

———

●

—

●

———

Printer not ready, data held in buffer

● ● ● ●

———

● ● ● ●

Computer ignoring flow control, data lost

Key:

●

Blink

—

Short pause

———

Long pause