6

Minimum Inlet supply gas pressure: L.P. 11”w.c. N.G. 7” w.c.

Maximum Inlet supply gas pressure: ½ P.S.I. (14” w.c.)

Required manifold pressure: L.P. 10.5” w.c. N.G. 3.5” w.c.

Maximum Input 50,000BTU L.P. & 50,000BTU Natural Gas

Maximum turn down pressure: 6.4” L.P. & 1.5” Natural Gas

WARNING (Care & Use of L.P. cylinders)

L.P. GAS CANNOT BE USED ON UNITS DESIGNED FOR NATURAL GAS.

NATURAL GAS CANNOT BE USED ON UNITS DESIGNED FOR L.P.

If your heater is designed for use with an L.P. cylinder, the cylinder must meet the following

requirements: cylinder weight is 20 lb. (9.07 kg): cylinder has outside diameter of 12-1/8 in.

(30.8 cm), length of 18 in. (45.7 cm) and is constructed and marked to specifications of the

U.S. Department of Transportation (D.O.T.) or Canadian Transport Commission (C.T.C.).

Cylinder has shut-off valve outlet which is a No. 510, female P.O.L.; a safety relief device

which has direct communication with vapour space of cylinder. Supply system is arranged

for vapour withdrawal. Cylinder includes collar to protect valve.

If your heater is to be used on L.P. gas, special precautions should be observed when

handling L.P. cylinders. Remember that this is gas and under pressure, which must be

handled with care. Ask your L.P. gas dealer to show you the necessary safety precautions

and check local codes for use, storage, and transport regulations. Among the recommended

practices are:

1. Always keep L.P. cylinders upright.

2. Do not subject L.P. cylinder to excessive heat.

3. Avoid damage to tank valves-handle them with care.

4. Never store L.P. cylinder indoors or in direct sunlight.

5. Do not handle L.P. cylinders roughly.

Follow instructions for connecting and disconnecting L.P. cylinders for the heater and be

sure to check all connections each time the cylinder is connected.

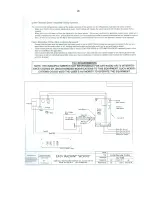

Choosing a Safe Location

Heaters must be installed on a secure and level surface.

Patio Plus heaters may be installed on a combustible surface. If the heater is installed

near a combustible wall or under a combustible ceiling, the minimum clearances to

combustibles described in the drawing on page 2 must be adhered to. The installation

must adhere to all local and applicable codes. In the absence of local codes, it must

adhere to current CAN/B149 in Canada or ANSI Z223.1 in the United States