www.parweld.com

www.parweld.com

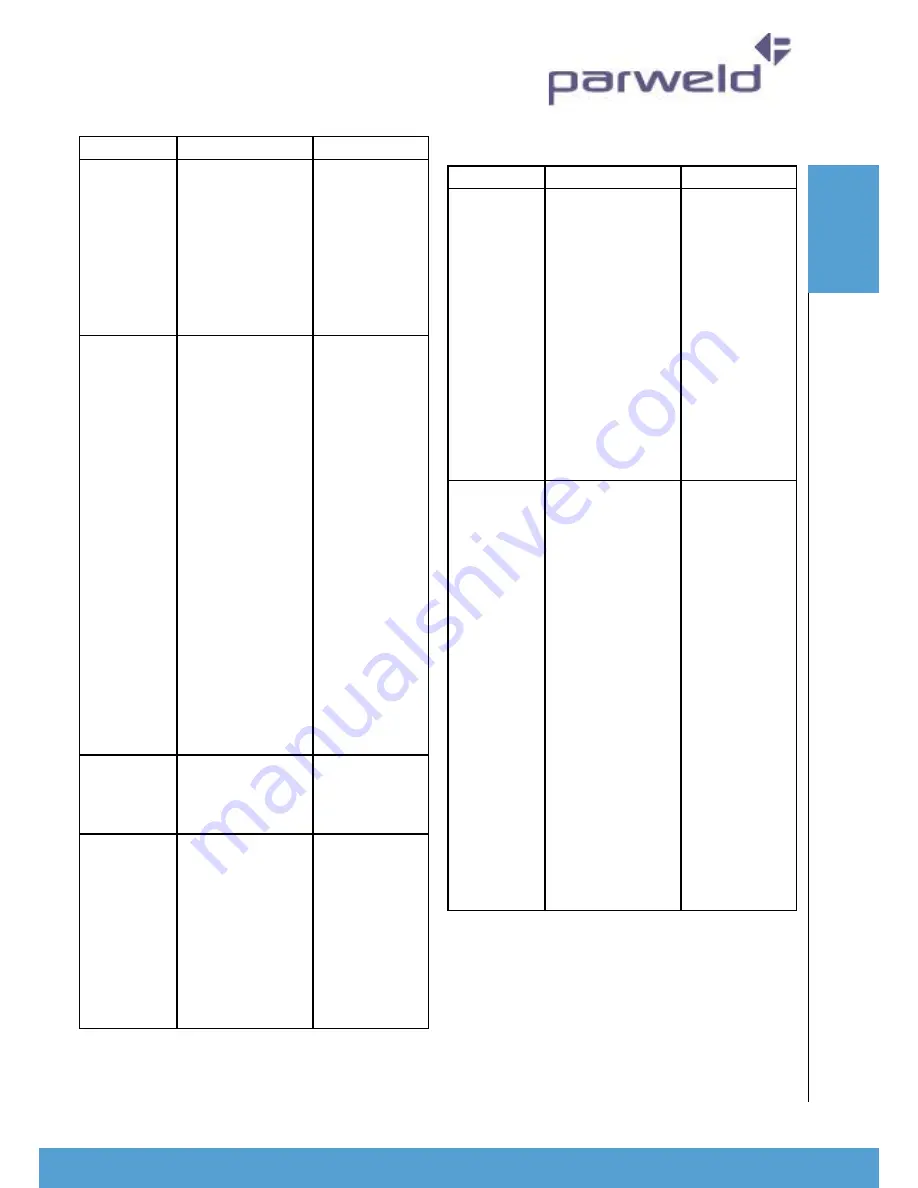

Description

Possible Cause

Remedy

Dirty weld

pool

(a) Electrode

contaminated

through contact

with work piece or

filler rod material

(b) Gas contami-

nated with air

(a) Clean the

electrode by

grinding off the

contaminates

(b) Check gas

lines for cuts

and loose fitting

or change gas

cylinder

Electrode

melts or

oxidizes

when an arc

is struck

(a) No gas flowing

to welding region

(b) Torch is clogged

with dust

(c) Gas hose is cut

(d) Gas passage

contains impurities

(e) Gas regulator is

turned off

(f) Torch valve is

turned off

(g) The electrode

is too small for the

welding current

(a) Check the

gas lines for

kinks or breaks

and gas cylinder

contents

(b) Clean torch

(c) Replace gas

hose

(d) Disconnect

gas hose from

torch then raise

gas pressure

to blow out

impurities.

(e) Turn on

(f) Turn on

(g) Increase

electrode

diameter or

reduce the

welding current

Poor weld

finish

Inadequate

shielding gas

Increase gas

flow or check

gas line for gas

flow problems

Arc flutters

during TIG

welding

(a) Tungsten

electrode is too

large for the

welding current

(b) Absence of

oxides in the Weld

pool.

(a) Select

the right size

electrode. Refer

to basic TIG

welding guide.

(b) Refer basic

TIG welding

guide for ways

to reduce arc

flutter

Description

Possible Cause

Remedy

Welding arc

cannot be

established

(a) Work clamp is

not connected to

the work piece or

the work/torch

leads are not

connected to the

machine

(b) Torch lead is

disconnected

(c) Gas flow

incorrectly set,

cylinder empty or

the torch valve is

off

a) Connect the

work clamp to

the work piece

or connect the

work/torch

leads to the

right welding

terminals.

(b) Connect it to

the ‘.’ terminal.

(c) Select the

right flow

rate, change

cylinders or turn

torch valve on.

Arc start is

not smooth

(a) Tungsten

electrode is too

large for the

welding current .

(b) The wrong

electrode is being

used for the

welding job.

(c) Gas flow rate is

too high.

(d) Incorrect

shielding gas is

being used.

(e) Poor work

clamp connection

to work piece

(a) Select

the right size

electrode

(b) Select the

right electrode

type. Refer

to basic TIG

welding guide

(c) Select the

correct rate for

the welding job.

Refer to basic

TIG welding

guide

(d) Select the

right shielding

gas. Refer

to basic TIG

welding guide

(e) Improve

connection to

work piece

Faul

t

FI

n

DI

n

G

13

Summary of Contents for XTI-601 MP

Page 1: ...INSTRUCTION MANUAL...