HY13-1526-001-M1/US

Torqmotor™ Service Procedure

TC, TS, TB, TE and TJ Series

Parker Hannifin Corporation

Hydraulic Pump/Motor Division

Greeneville, TN 37745 US

29

Remove end

cover &

inspect bolts

NOTE

Remove plugs

and valves

4. Remove end cover assembly (2). SEE FIG-

URE 10. After July 2012, motors no longer

have section seal ring located in the end

cover (2).

NOTE: Refer to the appropriate “alternate

cover construction” on the exploded view

to determine the end cover construction

being serviced.

5. If the end cover (2) is equipped with shuttle

valve or relief valve (22,24) components,

remove the two previously loosened plugs

(21,23). SEE FIGURE 11.

CAUTION

NOTE

NOTE

CAUTION: Be ready to catch the shuttle

valve or relief valve components that

will fall out of the end cover valve cavity

when the plugs are removed.

NOTE: O-ring (20) is not included in seal

kits but serviced separately if required.

NOTE: The orifice plug in the end cover

(2) must not be removed as they are ser-

viced as an integral part of the end cover.

Wash & inspect

end cover

NOTE

6. Thoroughly wash end cover (2) in proper

solvent and blow dry. Be sure the end cover

valve apertures, including the internal orifice

plug, are free of contamination. Inspect end

cover for cracks and the bolt head recesses

for good bolt head sealing surfaces.

Replace end cover as necessary.

NOTE: A polished pattern (not scratches)

on the cover from rotation of the commu-

tator (5) is normal. Discoloration would

indicate excess fluid temperature, ther-

mal shock, or excess speed and require

system investigation for cause and close

inspection of end cover, commutator,

manifold, and rotor set.

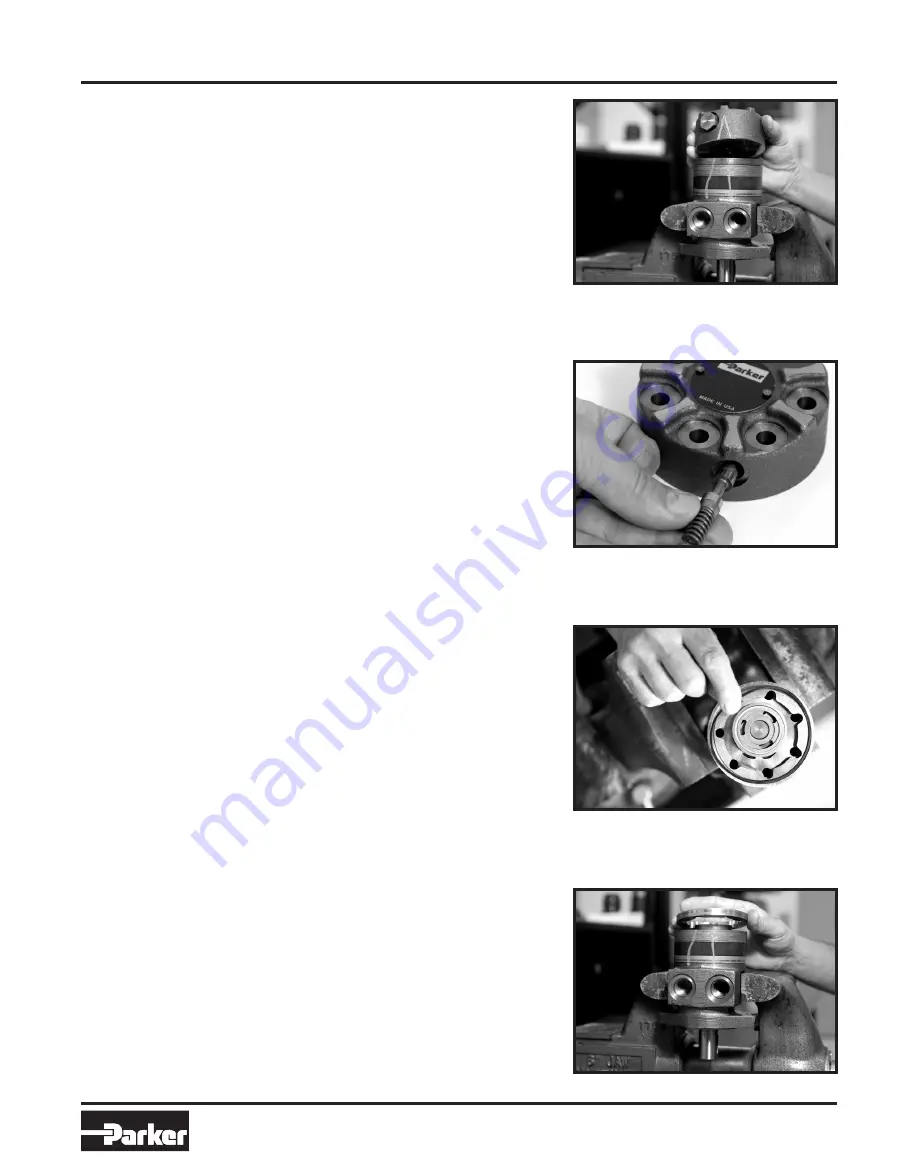

Remove

& inspect

commutator

ring

7. Remove commutator ring seal (3) and discard.

SEE FIGURE 12. Remove commutator ring (5).

Inspect commutator ring for cracks, or burrs.

SEE FIGURE 13.

Figure 13

Figure 12

Figure 11

Figure 10

Disassembly and Inspection