Installation and servicing manual

Shell & Tube Cooler

9

Parker Hannifin Corporation

Hydraulics Group

Catalogue HY10-6014-UM/CN

Maintenance Procedures

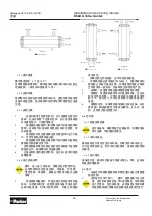

When reassembling the shell and tube cooler bundle into the

shell and tube cooler body, ensure to center the bundle in the

shell and tube body in order to avoid O-Ring damage when

assembling. Orientate the first baffle facing upwards (see

picture below) in order to guarantee product performance.

Follow star order tightening method (described from 1 to 8

in the picture below) when tightening the covers in order to

prevent any damage to the gasket.

Respect standards torques listed in Annex of the shell and tube

manual when tightening the bolts into the cooler.

After reassembly and prior to commissioning to the system,

pressure test the shell and tube cooler on the oil side and

water side independently at test pressure mentioned on the

product nameplate, in order to guarantee shell and tube cooler

proofness and leakage free.

Parker OLAER will not be held responsible for any damage to

the shell and tube cooler or hydraulic system caused by wrong

shell and tube cooler assembly and/or shell and tube cooler not

pressure tested prior commissioning to the hydraulic system.

Remove Gasket

Remove O-Ring

6.2 Replacing Casting Cover

6.2.1 WHEN TO REPLACE

The casting cover may be required to be replaced when oil or

cooling water leaks due to breakage of the cover.

6.2.2 HOW TO REPLACE

The steps are the same as the onces in O-ring or Gasket

Replacing. Refer to 5.1 REPLACING O-Ring or Gasket. Step 1

to 4 then change casting cover & repeat the step.

6.3 Cleaning of Copper Pipe

6.3.1 WHEN TO CLEAN

When the interior of copper tube is blocked due to any

foreign substance, the heat exchange rate drops. Clean every

6 months if used on application using non corrosive fluid

and equipped with filtration system. For coolant from other

origins, clean the shell and tube copper pipe every 4 months.

6.3.2 HOW TO CLEAN

Step 1 to 8 plus remove tube bundle.

9.

When the interior of COPPER tube is blocked due to any

foreign substance, clean interrior of COPPER tube.

10.

Ensure that you use a non-corrosive limestone diluents

as detergent when cleaning. Use the detergent in

accordance with the instructions provided by the

detergent manufacturer.