Installation and servicing manual

Shell & Tube Cooler

10

Parker Hannifin Corporation

Hydraulics Group

Catalogue HY10-6014-UM/CN

Emergency Measures/Warranty Repair

DO NOT clean OIL LINE with detergent used for copper

pipes. After fully understanding the usage instructions of the

detergent, keep the product completely sunk in a container

filled with the detergent for a period time.

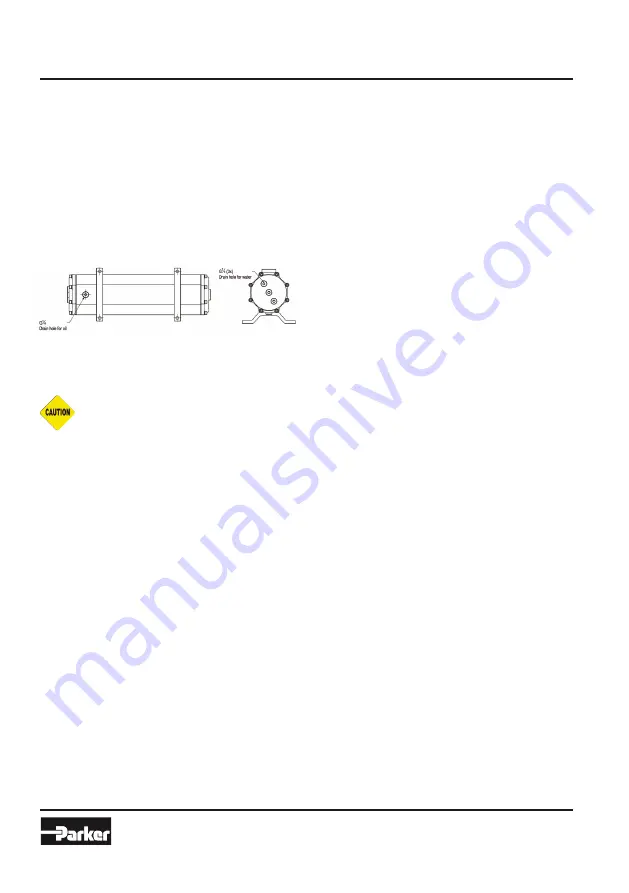

6.3.3 COOLER DRAINING

When the system is stopped and water is not supplied to the

heat exchanger anymore, ALL water drain plugs located on the

floating cover should be opened and water completely drained

out of the cooler.

Stagnant water leads to high corrosion level and reduce

drastically lifetime of the cooler.

Drain the cooler during winter season to avoid water freezing

and tubes bursting.

7. Emergency Measures

7.1 Measures for leakage by casting breakage

• Block pressure into the working system

immediately when the casting cover of equipment is

broken due to external shock.

• Discontinue the supply of cooling water to the

cooling line. Drain the tube side (refer to draining).

•

Unscrew the bolts screwed on the cover.

•

Remove O-ring and check whether or not it may be

reused, and if not, replaced.

•

Assemble a new casting cover with bolts as what it used

to be.

7.2 Replacement measures for copper pipe breakage

•

Immediately discontinue operation and supplying cooling

water to the cooling line when the copper pipe is broken

as a result of a freeze burst during colder seasons.

•

If cooling water continues being supplied continuously

when the copper tube is broken, water and oil may mix

inside the heat exchanger, which may result in damage

to your system. Please pay extra attention to this issue.

•

Broken copper pipe may not be repaired or replaced by

the customers.

Ensure that you consult and repair or replacement, via

appropriate services through after Sales Team or Local

Customer Service Center of Parker OLAER.

7.3 Emergency measures for Gasket breakage

1.

Discontinue operating the supplying line of cooling

water and the system when cooling water leaks due to

gasket breakage.

2.

Unscrew the bolts screwed on the casting cover.

3.

Remove gasket and insert a replacement.

4.

Reassemble the casting cover.

7.4 Measures for Water & Oil leagage in in-out let

1.

First, discontinue operating the system and the cooling

water line when oil or water leakes in IN-OUTLET.

2.

Check if nipple in IN-OUTLET is assembled properly. If it

is not fastened securely, water and oil may leak.

3.

For PT screws, water and oil leakage may be prevented

effectively by winding Teflon tape on it or by using it with

sealing materials.

4.

When water and oil leak due to defects in the cooler

other that those outline above, contact After Sales

Team or your nearest Customer Service Center of

Parker OLAER.

8. Warranty Repair &

Regional Service Network

8.1 Warranty Period

•

This product complies with strict quality management

and inspection regulations of PARKER OLAER

SUzHOU (OILTECH HYDRAULICS)

•

The warranty period of this product is prescribed as

1 year from the date of purchase, when used under

the working conditions described in the shell and tube

cooler manual.

8.2 Service Network

PARKER OLAER SUzHOU (OILTECH HYDRAULICS)

No. 2 workshop | #95 Weixin Road | Weiting | Suzhou

Jiangsu | P.R. China 215121

Tel: +86 512 6289 1000 | Fax: +86 6289 0805

Website: www.parker.com