PD42-1070 Hardware Manual • Hardware Version V1.00 | Document Revision V1.10 • 2018-July-03

12 / 25

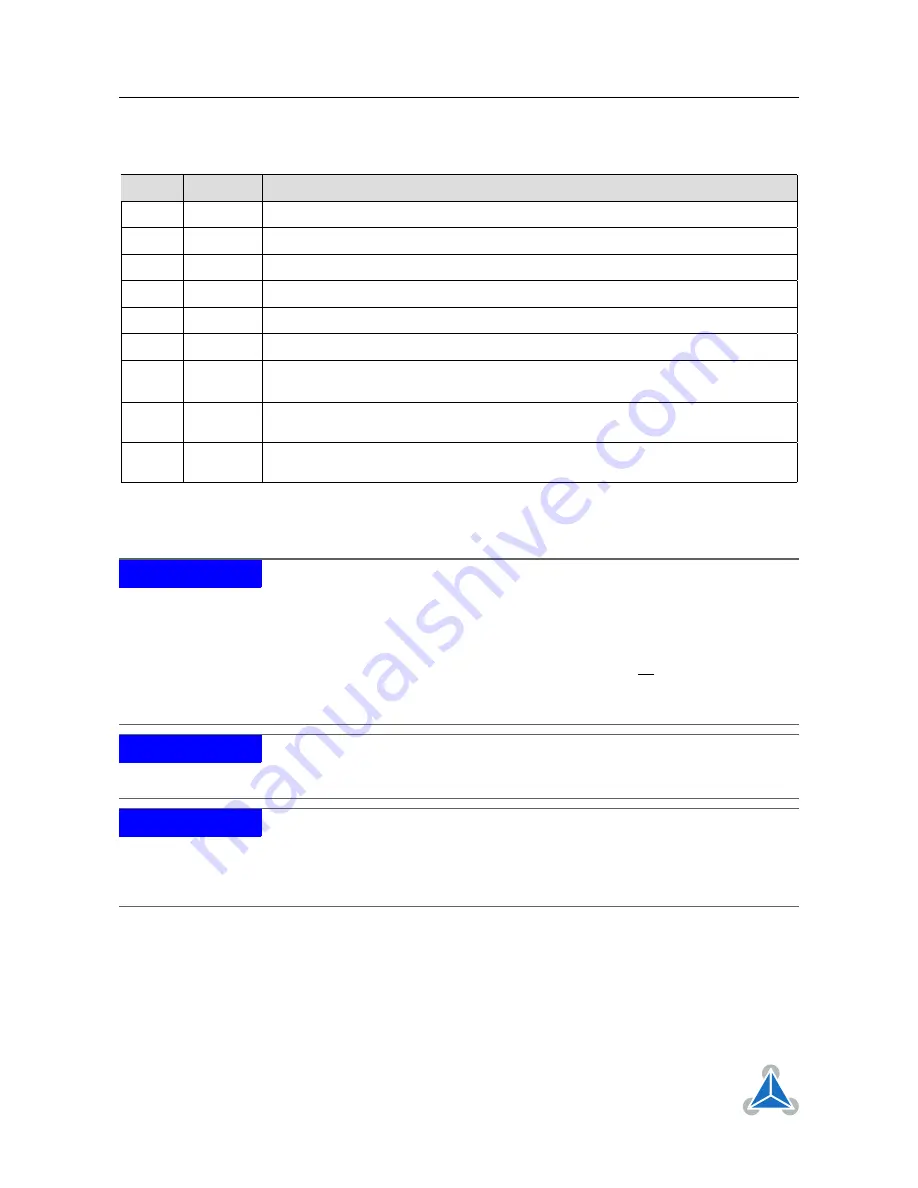

4.2 I/O Connector

Pin no. Pin name Description

1

GND

Supply ground connection, also used for USB serial converter ground connection

2

V+

Supply voltage (

V DD

) +9V to +28V DC

3

DIR

Optically isolated direction input of S/D interface

4

STEP

Optically isolated step input of S/D interface

5

EN

Optically isolated enable input of motor driver H-bridges

6

CHOP

Optically isolated chopper mode selection input

7

COMM

Opto-coupler common anode or cathode, connect to ground or VCCIO (3.3V to

24V)

8

RXD

TTL-level UART receive line, use with USB serial converter TXD line to connect to

PC

9

TXD

TTL-level UART transmit line, use with USB serial converter RXD line to connect to

PC

Table 6: I/O connector pinning

NOTICE

Supply Voltage Buffering / Add External Power Supply Capacitors

A sufficiently buffered power supply or an external electrolyte capacitor

connected between V+ and GND is recommended for stable operation.

It is recommended to connect an electrolytic capacitor of significant size to the

power supply lines next to the PD42-1070.

Rule of thumb for size of electrolytic capacitor:

C

= 1000

µF

A

∗

I

SU P P LY

The PD42-1070 comes with approximately 40

µ

F of onboard ceramic capacitors.

NOTICE

There is no reverse polarity protection on the supply input!

The module will short any reversed supply voltage and board electronics will get

damaged.

NOTICE

Power Up Sequence

The PD42-1070 must be powered up with disabled driver stage only. Depending

on your configuration the EN input should be logically OFF. For example, if COMM

input is connected to 3.3V to 24V, the EN input must be 0V. If common ground or

0V level is connected to COMM input, the EN input must have high level.

©2018 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at

www.trinamic.com