1

INSTALLATION PLACE AND POWER SOURCE FACILITY

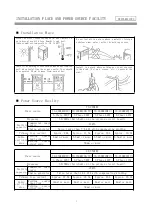

Installation Place

Power Source Facility

Power source

YD-200KR2

YD-200KR2HD□ YD-200KR2HG/N□ YD-200KR2HK□

YD-200KR2HJ□

3-Phase 220V

3-Phase 380V

3-Phase 440V

3-Phase 415V

Frequency

50/60Hz (Switchable on the printed circuit board)

Facility

capacity

Commercial power

source

10kVA

Engine generator

Twice large than 7.6 kVA with compensating winding.

Primary line current

Approx. 20A

Approx. 11.5A

Approx. 10A

Approx. 10.6A

Cable

sectional

area

Welding

source

input side

8mm

2

or more

5.5mm

2

or more

5.5mm

2

or more

5.5mm

2

or more

Welding

source

output side

38mm

2

or more

Power source

YD-350KR2

YD-350KR2HD□ YD-350KR2HG/N□ YD-350KR2HK□

YD-350KR2HJ□

3-Phase 220V

3-Phase 380V

3-Phase 440V

3-Phase 415V

Frequency

50/60Hz (Switchable on the printed circuit board)

Facility

capacity

Commercial power

source

20kVA

Engine generator

Twice large than 18.1 kVA with compensating winding.

Primary line current

Approx. 47.5A

Approx. 27.5A

Approx. 23A

Approx. 25.2A

Cable

sectional

area

Welding

source

input side

14mm

2

or more

8mm

2

or more

8mm

2

or more

8mm

2

or more

Welding

source

output side

38mm

2

or more

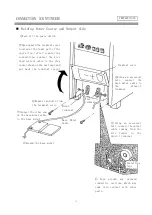

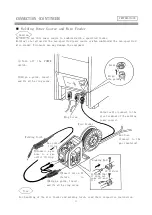

PREPARATIONS

Avoid the direct sunshine and rain, and install in

an indoor place with less humidity and dust.

(Indoor ambient temperature -10 to 40℃)

Install the welding source 20cm or more away from the

wall: when installing two or more units, they should

be separated 30 cm or more from each other.

Do not install in a place where a metallic foreign

substance may enter inside the welding source.

Install in a place where welding arc is not exposed

to the wind. (Set up a screen. etc. to prevent the

wind.)