ACTION

POSITION

TIME ms*

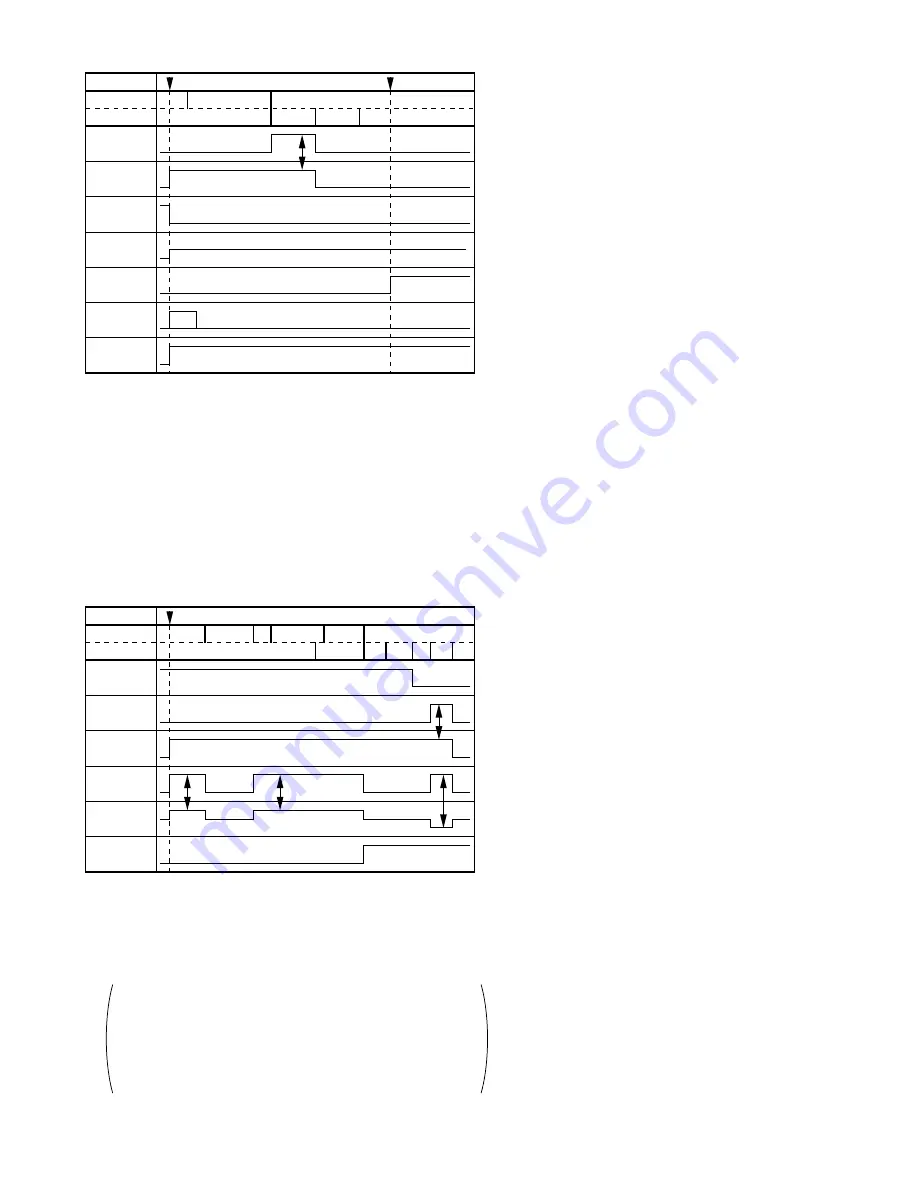

TIMING CHART 8

STOP

2.6S

8

7

8-1

8-2

8-3

M

100

LOADING

FWD(H)

(PIN 10)

LOADING

REV(H)

(PIN 9)

CAPSTAN

R(H)/S(M)/F(L)

(PIN 42)

10

NOTE: 1) PIN NO. WITH BRACKET INDICATES PIN NO. OF IC6001.

2) *:IT SHOWS MAXIMUM TIME.

MODE BY MODE OPERATION

8. PLAY TO STOP/AFTER 10 MINUTES

8-1. The Mechanism changes the position to 7(Stop).

8-2. The Loading Motor stops.

At this position, the Pressure Roller and the Tension Arm are released to

reduce the tape tension.

8-3. After 5 minutes, the Cylinder stops.

5 MINUTES

AUDIO

MUTE(H)

(PIN 5)

ACTION

POSITION

TIME ms*

TIMING CHART 9

T-PHOTO TR

ON(L)

(PIN 83)

LOADING

FWD(H)

(PIN 10)

LOADING

REV(H)

(PIN 9)

CAPSTAN

R(H)/S(M)/F(L)

(PIN 42)

EJECT

4S

7S

5.1S

1

2

3

4

6/5

7

200

9-3

9-5

9-1

9-4

9-6

M

H

M

M

H

NOTE: 1) PIN NO. WITH BRACKET INDICATES PIN NO. OF IC6001.

2) *:IT SHOWS MAXIMUM TIME.

MODE BY MODE OPERATION

9. STOP TO EJECT

9-1. Unloads the mechanism to the Eject position(1).

9-2. The Idler Gear swings over to Supply Reel.

9-3. The Capstan Motor rotates in reverse direction to takeup a tape slack.

9-4. When the Mode Switch reaches position 1, the Cylinder stops.

9-5. T-Photo Tr signal goes LOW at position 1.

If T-Photo Tr signal does not become LOW within 4 seconds at position 1,

the mechanism moves to position 7.

If the mechanism does not reach position 3 within 2.6 seconds, or does not

reach position 4 from position 3 within 3 seconds after that, the mechanism

moves to position 1.

If T-photo Tr signal does not become Low within 4 seconds again, the unit

shuts off.

(For Auto Eject operation, if T-photo Tr signal does not become Low within

4 seconds at position 1, the mechanism moves to position 3 and the unit

shuts off.)

9-6. The Loading Motor stops.

9-7. The Idler Gear is released from Supply Reel.

500

20

L

CAPSTAN

ON(H)

CYLINDER

ON(L)

PB(L)

(PIN 6)

CAPSTAN

ON(H)

CYLINDER

ON(L)

9

PLAY

REC

9-2

9-7

Summary of Contents for PV-4601 A

Page 14: ...Fig 2 3 14 ...

Page 27: ...Fig 11 1 1 27 ...

Page 40: ...Fig D1 40 ...

Page 42: ...Fig D2 42 ...

Page 43: ...Fig D3 43 ...

Page 44: ...Fig D4 44 ...

Page 45: ...Fig D5 45 ...

Page 46: ...Fig D7 46 ...

Page 47: ...Fig D8 47 ...

Page 51: ...Fig M2 1 Fig M2 2 51 ...

Page 53: ...Fig M4 1 53 ...

Page 77: ...Fig M19 77 ...

Page 84: ...Fig J5 84 ...

Page 85: ...Fig J6 85 ...

Page 87: ...Fig J9 87 ...

Page 88: ...Fig J10 88 ...

Page 89: ...Fig J11 89 ...

Page 90: ...Fig J12 90 ...

Page 91: ...Fig J13 91 ...

Page 92: ...Fig J15 92 ...

Page 93: ...93 ...

Page 96: ...96 ...

Page 102: ...with the holes on the Pinch Lift Cam as shown in Fig A6 102 ...

Page 103: ...103 ...

Page 105: ...Fig K1 105 ...

Page 106: ...Fig K2 106 ...

Page 107: ...Fig K3 107 ...

Page 109: ...Fig B1 109 ...

Page 114: ...Fig E1 4 3 2 HOW TO READ THE ADJUSTMENT PROCEDURES 114 ...

Page 115: ...Fig E2 115 ...

Page 134: ...R6004 ERJ6GEYJ333V MGF CHIP 1 10W 33K 134 ...

Page 136: ...R6085 ERJ6GEYJ223V MGF CHIP 1 10W 22K 136 ...

Page 140: ...C4601 ECEA1CKA100 ELECTROLYTIC 16V 10 140 ...

Page 147: ...R6065 ERJ6GEYJ223V MGF CHIP 1 10W 22K 147 ...

Page 167: ...9 11 Operation Block Diagrams 1 167 ...

Page 178: ......

Page 204: ......

Page 205: ......