128

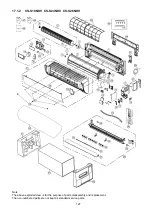

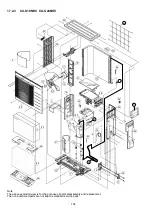

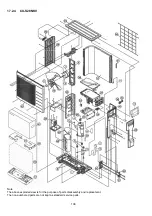

REF.

NO.

PART NAME & DESCRIPTION

QTY.

CS-S18NKV CS-S24NKV CS-S28NKV

REMARK

1 CHASSIS

COMPLETE

1 CWD50C1604

←

←

2 FAN

MOTOR

1 ARW7628AC ARW7627AC

←

O

3

CROSS-FLOW FAN COMPLETE

1

CWH02C1077

←

←

4 BEARING

ASSY

1 CWH64K007

←

←

5

SCREW - CROSS-FLOW FAN

1

CWH551146

←

←

6 GENERATOR

COMPLETE

1 CWH94C0043

←

←

7 EVAPORATOR

1 CWB30C3198 CWB30C3654 CWB30C3766

8

FLARE NUT (LIQUID)

1

CWT251030

←

←

9

FLARE NUT (GAS)

1

CWT251032

CWT251033

←

10

CLIP FOR SENSOR

1

CWH32143

←

←

11

CONTROL BOARD CASING

1

CWH102449

←

←

12

TERMINAL BOARD COMPLETE

1

CWA28C2439

CWA28C2441

←

O

13

ELECTRONIC CONTROLLER - MAIN

1 CWA73C6247 CWA73C6248 CWA73C6249

O

14

ELECTRONIC CONTROLLER - HVU

1

N0GE1F000002

←

←

O

15

ELECTRONIC CONTROLLER - INDICATOR

1

CWA746634

←

←

O

16 SENSOR

COMPLETE

1 CWA50C2401

←

CWA50C2782

O

17

SENSOR COMPLETE (ECO)

1

CWA50C2826

←

←

O

18

ELECTRONIC CONTROLLER (ECO SENSOR)

1

CWA745791

←

←

O

19

ELECTRONIC CONTROLLER (ECO SENSOR)

1

CWA746206

←

←

O

20 ELECTRONIC

CONTROLLER

(COMPARATOR)

1 CWA746653

←

←

O

21

LEAD WIRE - PCB ECO

1

CWA67C9934

←

←

22

CONTROL BOARD CASING FOR PCB ECO

1

CWD933407A

←

←

23

CONTROL BOARD TOP COVER

1

CWH131467

←

←

24 INDICATOR

HOLDER

1 CWD933406

←

←

25

CONTROL BOARD FRONT COVER CO.

1

CWH13C1247

←

←

26

DISCHARGE GRILLE COMPLETE

1

CWE20C3244

←

←

27 BACK

COVER

CHASSIS

1 CWD933031A

←

←

28 FULCRUM

2 CWH621138

←

←

29 VERTICAL

VANE

11 CWE241374

←

←

30 CONNECTING

BAR

1 CWE261257

←

←

31 CONNECTING

BAR

1 CWE261258

←

←

32

AIR SWING MOTOR

1

CWA98K1018

←

←

O

33

AIR SWING MOTOR

1

CWA981241

←

←

O

34

CAP - DRAIN TRAY

1

CWH521096

←

←

35

HORIZONTAL VANE COMPLETE

1

CWE24C1392

CWE24C1395

←

36 REMOTE

CONTROL

COMPLETE

1 CWA75C3865

←

←

O

37

FRONT GRILLE COMPLETE

1

CWE11C5129

←

CWE11C5130

O

38

INTAKE GRILLE COMPLETE

1

CWE22C1729

←

←

39

GRILLE DOOR COMPLETE

1

CWE14C1091

←

←

40 AIR

FILTER

2 CWD001283

←

←

41

SCREW - FRONT GRILLE

3

XTT4+16CFJ

←

←

42

CAP - FRONT GRILLE

3

CWH521227A

←

←

43 DRAIN

HOSE

1 CWH851174

←

←

44 INSTALLATION

PLATE

1 CWH361098

←

←

45

BAG COMPLETE - INSTALLATION SCREW

1

CWH82C1705

←

←

46 OPERATING

INSTRUCTION

1 CWF568408

←

←

47 INSTALLATION

INSTRUCTION

1 CWF615273

←

CWF615084

48 INSTALLATION

INSTRUCTION

1 CWF615274

←

CWF615085

49

POWER SUPPLY CORD

1

CWA20C2851

CWA20C2853

←

Summary of Contents for CS-S9NKV

Page 15: ...15 4 2 3 CU S18NKV CU S24NKV...

Page 16: ...16 4 2 4 CU S28NKV...

Page 17: ...17 5 Refrigeration Cycle Diagram 5 1 CS S9NKV CU S9NKV CS S12NKV CU S12NKV...

Page 18: ...18 5 2 CS S18NKV CU S18NKV CS S24NKV CU S24NKV...

Page 19: ...19 5 3 CS S28NKV CU S28NKV...

Page 24: ...24 7 Wiring Connection Diagram 7 1 Indoor Unit 7 1 1 CS S9NKV CS S12NKV...

Page 25: ...25 7 1 2 CS S18NKV CS S24NKV...

Page 26: ...26 7 1 3 CS S28NKV...

Page 31: ...31 8 Electronic Circuit Diagram 8 1 Indoor Unit 8 1 1 CS S9NKV CS S12NKV...

Page 32: ...32 8 1 2 CS S18NKV CS S24NKV...

Page 33: ...33 8 1 3 CS S28NKV...

Page 41: ...41 9 1 5 Human Activity Sensor Printed Circuit Board...

Page 42: ...42 9 2 Outdoor Unit 9 2 1 Main Printed Circuit Board 9 2 1 1 CU S9NK...

Page 43: ...43 9 2 1 2 CU S12NK...

Page 44: ...44 9 2 1 3 CU S18NK CU S24NK...

Page 45: ...45 9 2 1 4 CU S28NK...

Page 46: ...46 9 2 2 Noise Filter Printed Circuit Board 9 2 2 1 CU S9NKV...

Page 47: ...47 9 2 2 2 CU S28NKV...