System Operations Manual

www.paceworldwide.com

Page 4 of 40

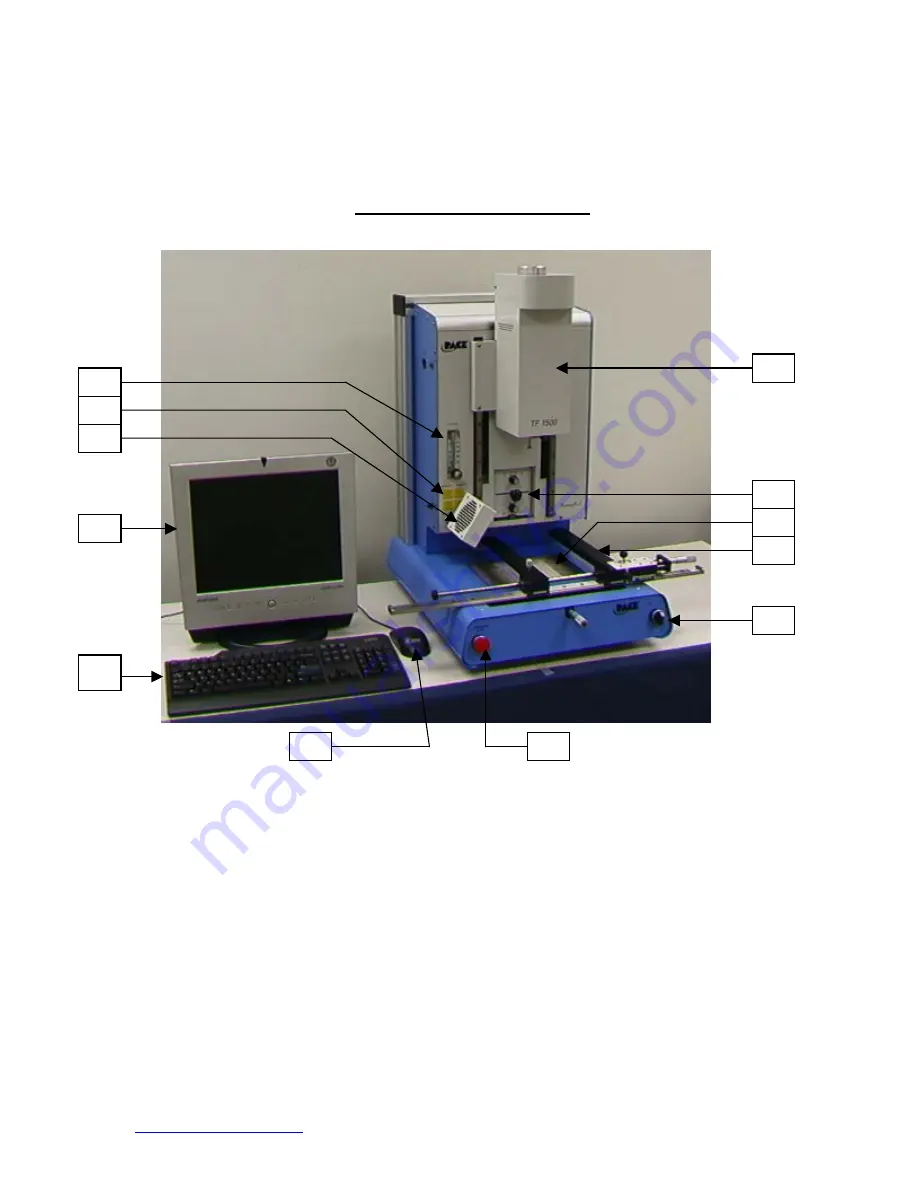

TF 1500 Parts Identification

Figure 1

A. Air Flow Meter

This device is used to control and monitor the airflow

through the reflow head.

B. Sensor Input

The sensor inputs are K-type thermo-couples.

Measured temperatures are displayed through the PC

software in real time for use in making profile graphs.

C. Cooling Fan

The component and PCB are cooled by the cooling fan,

which can be set to activate automatically after the

reflow cycle is complete or operated manually.

D. LCD Display Monitor

Displays PC software.

E. Keyboard

Used to enter information into software.

F. Reflow Head

Contains the top-side heater and moves up and down

via an electric motor that is controlled through the

software. The reflow head is clutched to prevent

excessive downward force from being applied.

A

B

C

D

E

F

G

H

I

J

K

L