the bevel pinion and seat securely against the pump drive

pinion. Install bearing cone set spacer on to the bevel pin-

ion.

Install the bearing cup retaining ring into the groove in the

carrier bore.

Place the carrier assembly onto bench with the pump side

facing up. Install one bearing cup of bearing set (1) and

seat against the retaining ring.

Turn the carrier over so that the pump side faces down.

Install the bearing cup spacer with the shoulder inside of

the retaining ring. Install the remaining bearing cup and

seat firmly against the bearing cup spacer and retaining

ring.

Place the carrier over the bevel pinion so that the pump

side bearing cup seats on the bearing cone.

Press the remaining bearing cone securely onto the bevel

pinion, seating into the bearing cup.

Lubricate and install O-Ring (5) onto the bevel pinion

against the bearing cone. Install seal spacer (9) over the

bevel pinion with internal tapered edge toward the bear-

ing cone and O-Ring.

Install the oil seal retaining ring (7) into the carrier bore

groove. Apply non-hardening sealant to the outside sur-

face of the oil seal (8) and install the oil seal firmly against

the retaining ring (7).

Install the bearing lockwasher (4) and locknut (2) onto the

bevel pinion. Tighten the locknut to 150 lb•ft (203 N•m)

torque and bend tang of lockwasher (4) into slot of lock-

nut.

Spacer, Bearing Cup

Retaining Ring

Bearing Cup

Bearing Cup

Carrier

Seal Sleeve

O-Ring

Bearing Cone

Bearing Cone

Set Spacer, Bearing Cone

Pinion, Pump Drive

Bevel Pinion

Apply LocTite

601 Here

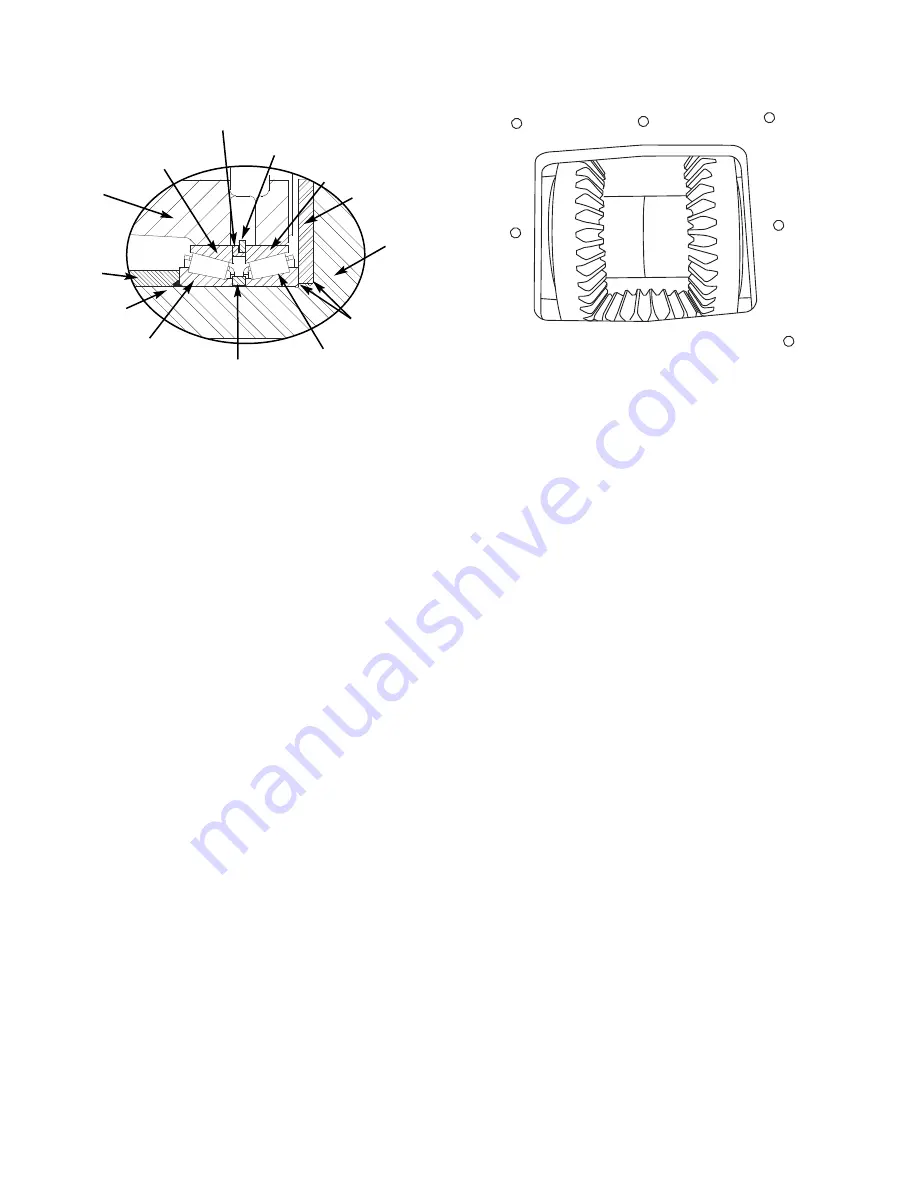

BEVEL PINION CARRIER INSTALLATION

Apply gear tooth marking compound to bevel pinion and

install carrier assembly into winch case using the original

shim set. Replace gasket as required. Tighten capscrews

to 75 lb•ft (102 N•m) torque.

Rotate bevel pinion in same direction as PTO shaft rota-

tion and check bevel pinion/gear tooth contact pattern.

See typical contact patterns, next page.

Remove carrier assembly to add or remove shims to

obtain the correct tooth contact pattern illustrated below.

Refer to Clutch Shaft Service for bevel gear backlash

adjustment procedure.

Upon final installation of carrier assembly, apply non-

hardening thread sealant to capscrews and tighten to 75

lb•ft (102 N•m) torque.

Refill winch to proper level with recommended lubricant.

30

Summary of Contents for CARCO 50B

Page 2: ......

Page 13: ...WIRING HARNESS 70A for D6R Series II 11...