18

TROUBLESHOOTING

A

The winch will not lower

the load or will not lower

smoothly

1. Clogged brake release air line or a

malfunctioning Quick Exhaust

valve. On units approved for per-

sonnel handling, an orifice in the

elbow fitting off of the control valve

could be plugged.

2. Defective brake cylinder seal.

3. If the brake was recently rebuilt,

the problem may be improper

assembly.

4. Band brake is not properly adjust-

ed or is dragging on winch drum.

Install a gage into the brake release line down-

stream of the quick exhaust valve and ensure

pressure is greater than 45 psi.

Perform air pressure test. Pressurize the

brake cylinder to 50 – 90 psi. If brake cylinder

will not hold pressure, seal is defective.

Disassemble and inspect the brake. Ensure

proper number of brake plates and friction

discs are used.

Adjust band brake as defined in “Band Brake

Adjustment” section of this manual.

B

Air leaks from the vent

plug

1. Defective brake cylinder seal or

motor shaft seal.

Perform air pressure test. Pressurize the

brake cylinder to 50 – 90 psi and ensure it

holds pressure.

If the brake pressure holds, the problem is the

motor shaft seal. Remove the motor for

inspection of the shaft seal.

TROUBLE

PROBABLE CAUSE

REMEDY

If a winch ever exhibits any sign of erratic operation, or load control difficulties (i.e.

load creeping or chattering), appropriate troubleshooting tests and repairs should

be performed immediately. Continue operation in this manner may result in prop-

erty damage, serious personal injury or death.

CAUTION

WARNING

!

!

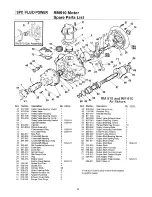

Summary of Contents for BRADEN BA3A

Page 2: ......

Page 25: ...23 THIS PAGE INTENTIONALLY LEFT BLANK...

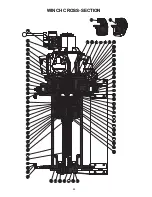

Page 26: ...24 WINCH CROSS SECTION...

Page 35: ...33...

Page 37: ......