19

C

The brake will not hold the

load with the control lever

in neutral.

1. Pressure is trapped in the brake

piston because of a faulty quick

exhaust valve.

2. Friction brake will not hold due to

worn of damaged brake discs.

3. Brake clutch is slipping

Slowly loosen fitting downstream of quick

exhaust valve. Air escaping through loose fit-

ting will verify that the quick exhaust valve is

not bleeding air pressure.

Disassemble brake and inspect brake discs.

Improper planetary gear oil may cause the

brake clutch to slip. Drain the gear oil and

flush with solvent. Completely drain the sol-

vent and fill with planetary gear oil listed in the

“Preventative Maintenance” section of this

manual.

Brake clutch may be damaged or worn.

Disassemble and inspect brake clutch as

described in the “Brake Clutch

D

The winch will not hoist

the rated load.

1. The winch may be mounted on an

uneven or flexible surface which

causes distortion of the winch base

and binding of the gear train.

Binding in the gear train will absorb

horsepower needed to hoist the

rated load and generate heat.

2. Inadequate air system pressure.

3. Layer on the winch drum is not

rated for load.

4. Rigging and sheaves are not work-

ing efficiently.

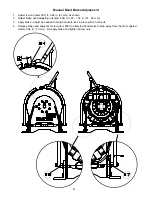

5. Band brake is not properly adjust-

ed or is dragging on winch drum.

Reinforce mounting surface.

If needed, use shim stock to level the winch.

Refer to “Winch Installation” instructions.

Loosen and then torque mounting bolts to rec-

ommended torque.

Install gage at air motor inlet and check air

pressure.

Refer to winch performance charts in the sales

brochure.

Perform rigging service as recommended by

the crane manufacturer.

Adjust band brake as defined in “Band Brake

Adjustment” section of this manual.

TROUBLE

PROBABLE CAUSE

REMEDY

Summary of Contents for BRADEN BA3A

Page 2: ......

Page 25: ...23 THIS PAGE INTENTIONALLY LEFT BLANK...

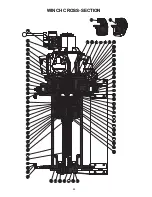

Page 26: ...24 WINCH CROSS SECTION...

Page 35: ...33...

Page 37: ......