- 14 -

4.

Care and Maintenance

4.1

Blade guides

Thanks to plastic linings the spade guides do not require lubrication.

Once the plastic lining has been worn to the point were the heads of the countersunk

screws are even with the surface of the plastic linings, they must be replaced to prevent

the screws from damaging the blades.

4.2

All moving parts of the tree spade must be greased at least once per week. The greasing

points are shown on the lubrication charts (pages 15 and 16).

4.3

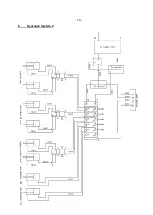

The oil level of the hydraulic system is controlled by the cabin computer of the Volvo truck.

Refill oil whenever necessary. For specification of hydraulic oil, please refer to data sheet

attached as annex.

In order to avoid any damages to the hydraulic system and related components, samples

of the hydraulic oil must be taken regularly. In case the impurities in the oil exceed purity

class 19/15/11 as defined by ISO 4406, the hydraulic oil must be changed. This is

extremely important because regular sampling is precondition for any damages claim.

The first sampling and examination must be made after 50 working hours, each following

sampling becomes due after every 1000 working hours.

4.4

All hydraulic hose pipes must get inspected thoroughly at least once per year. Defective

hose pipes must be replaced.

After six years all hose pipes must get replaced.

4.5

In case the tree spade is not getting used for two weeks, all piston rods of the hydraulic

cylinders must be cleaned and covered with a preserving oil film.

IMPORTANT: When doing cleaning, maintenance or repair work, lower the tree

spade to the ground and stop the truck engine.

When fixing the guides, the bolts (see Spare Parts List, Table 2, item

19) must be tightened with a torque of 1450 Nm (1070 ft-lbs.)

Use original spare parts only.

The tree spade must be inspected by an safety expert once a year.

Do not modify the equipment unless the manufacturer has given his

approval.