Chapter 1: Viper ePLC Robot Quick Setup

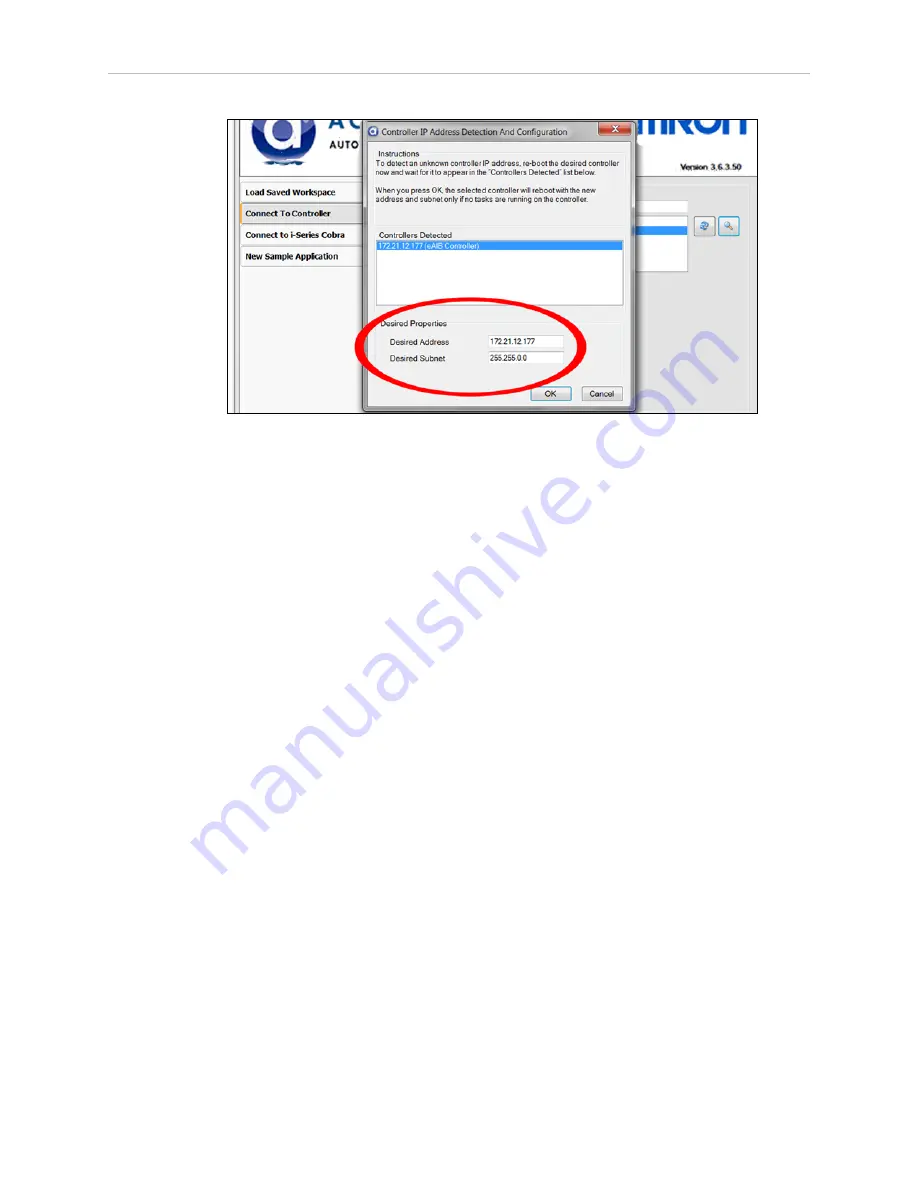

Figure 1-7. IP Addresses Detected

4. You can change the IP address and subnet mask in the Desired Address and Desired

Subnet fields, if needed.

5. Click OK. The ACE software will ask you to wait for the controller to reboot.

Configuring the Omron PLC

Refer to the EtherNet/IP Connection Guide (P649-E1-01) for configuring the Omron PLC to

work with Omron Adept robots. Refer to Resources on Omron Web Sites on page 3.

Using your PLC software, set the IP address for the PLC to connect to on the robot.

Enabling High Power

The details of enabling high power to the robot are covered in the EtherNet/IP Connection

Guide (P649-E1-01).

Once high power is enabled, the Robot Status Panel displays ON, and the amber Robot Status

LED is on.

1.7 Finding Additional Information

Installing Optional Equipment

For details on installing optional equipment, see the following topics in the Optional Equip-

ment Installation chapter of the Viper s650/s850 Robot User’s Guide:

l

Installing end-effectors

l

Connecting user air and electrical lines to user connection panel

l

Mounting external equipment on the robot

l

Mounting the robot solenoid option kit

Viper ePLC650/850 Quick Setup Guide, 13589-000 Rev D

Page 11 of 14

Summary of Contents for Viper 650 ePLC

Page 1: ...I600 E 01 Viper 650 850 ePLC Quick Setup Guide...

Page 13: ......