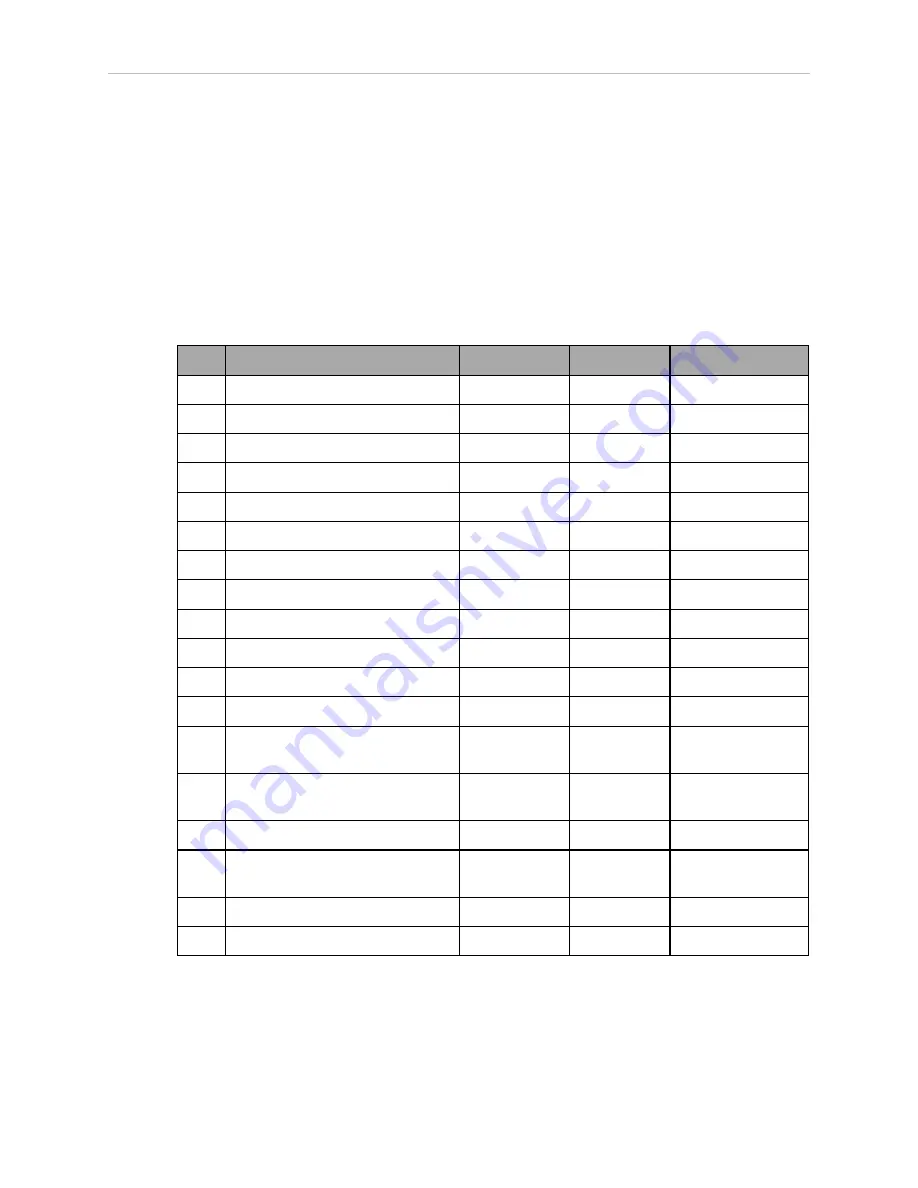

1.5 System Cable Connections

NOTE:

Check the tightness of the mounting bolts one week after initial installation,

and then recheck every 6 months. For periodic maintenance, refer to the Quattro

User’s Guide.

1.5 System Cable Connections

Open the Accessory box and locate the eAIB XSYSTEM cable. Connect the cables and peri-

pherals as shown in the following figure. Parts and steps are covered in the following two

tables. Refer to the System Installation chapter in your

Quattro User's Guide

for power spe-

cifications and wiring instructions.

Part

Cable and Parts List

Part #

Part of:

Notes

A

eAIB XSYSTEM Cable Assembly

13323-000

standard, eAIB

B

User E-Stop, Safety Gate

n/a

n/a

user-supplied

C

XUSR Jumper Plug

04736-000

13323-000

standard, eAIB

D

Front Panel

90356-10358

standard

E

Front Panel Cable

10356-10500

90356-10358

standard

F

Front Panel Jumper Plug

10053-000

13323-000

standard, eAIB

G

XMCP Jumper Plug

04737-000

13323-000

standard, eAIB

H

T20 Bypass Plug

10048-000

10055-000

standard, T20

J

T20 Adapter Cable

10051-003

10055-000

standard, T20

K

T20 Pendant (option)

10055-000

option

L

AC Power Cable (option)

04118-000

90565-010

user-supplied

M

24 VDC Power Cable (option)

04120-000

90565-010

user-supplied

N

24 VDC, 6 A Power Supply

(option)

04536-000

90565-010

user-supplied

P

Ethernet Cable - PC -> PLC

(Only while programming PLC)

n/a

n/a

user-supplied

Q

Ethernet Cable - PLC -> switch

n/a

n/a

user-supplied

R

Ethernet Cable - switch ->

SmartVision MX

n/a

n/a

user-supplied

S

Ethernet switch, cable

n/a

n/a

user-supplied

T

Camera and cable

n/a

n/a

option

Power Requirements

The power requirements for the SmartVision EX and the Quattro robots are covered in their

respective user guides. For 24 VDC, both can be powered by the same power supply.

Quattro ePLC650/800 Quick Setup Guide, 13588-000 Rev D

Page 8 of 16

Summary of Contents for Quattro 650H

Page 1: ...I598 E 01 Quick Setup Guide Quattro 650H 650HS 800H 800HS ePLC...

Page 14: ......

Page 15: ......