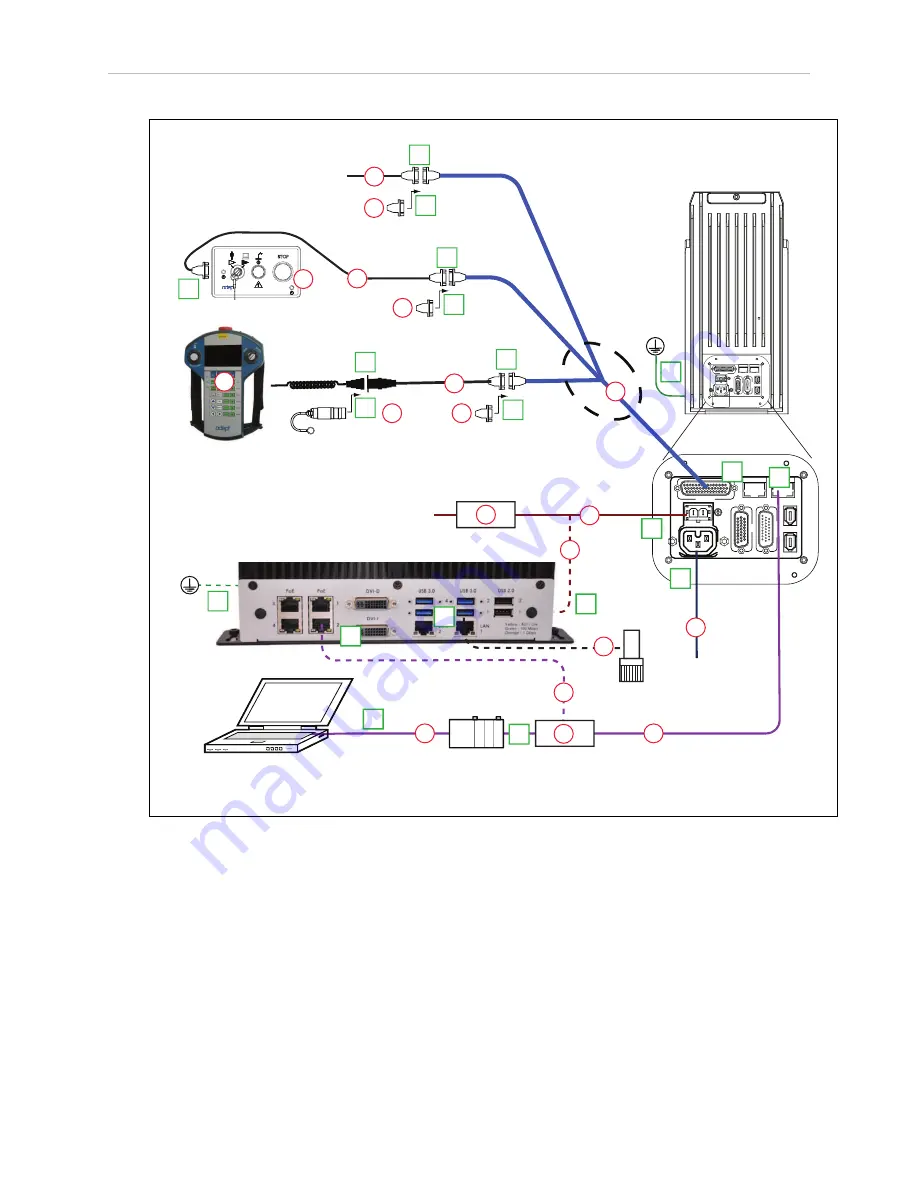

1.6 Configuration

DC

IN

24 V

GND

AC

200 -

240 V

Ø

1

XBEL

TI

O

XIO

Servo

ENET

ENET

XSYSTEM

ePLC Quattro Robot

24 VDC, 6 A

Power Supply

200-240 VAC

10 A

single-phase

AC Power

Cable

DC Power

Cable

Front Panel

Cable

Front Panel

User-Supplied PC

running PLC

Programming Software

T20 Adapter

Cable

XMCP Jumper Plug

XMCP

XFP

XUSR

XUSR Jumper Plug

eAIB

XSYSTEM

Cable

Robot Interface

Panel

XUSR for:

- User E-Stop/Safety Gate

- Muted Safety Gate

The Jumper Plug is required if

neither of these is used

Ethernet from

PC to PLC

T20 Bypass Plug

User-Supplied

Ground Wire

T20 Pendant (option)

Either T20 Pendant,T20 Bypass Plug, or

XMCP Jumper Plug must be used

2

3

4a

A

B

G

H

J

4a

4

4

1

5

6

7

9

8

L

M

Q

P

E

K

D

N

3

85 - 264 VAC

Universal

Input

DC

IN

24V

GND

AC

200 -

240V

Ø

1

XBEL

TIO

XIO

Servo

ENET

ENET

XSYSTEM

Ethernet from

PLC to eAIB

FP Jumper Plug

F

Either Front Panel or

FP plug must be used

3a

2a

C

Ethernet from eAIB

to SmartVision MX

R

9b

9a

User-supplied

Switch

SmartVision MX (option)

Camera

(option)

User-Supplied

Ground Wire

5a

7a

M

T

10

DC Power

Cable

S

PLC

Figure 1-4. Configuration with Vision

1.6 Configuration

The user-supplied PLC and the Quattro robot are connected either through a shared network or

via a user-supplied Ethernet cable.

When the Quattro ePLC robot is powered on and waiting for a PLC connection, the robot

status panel will display its IP address, two digits at a time.

The format will be:

IP xxx-xxx-xxx-xxx OK

Quattro ePLC650/800 Quick Setup Guide, 13588-000 Rev D

Page 10 of 16

Summary of Contents for Quattro 650H

Page 1: ...I598 E 01 Quick Setup Guide Quattro 650H 650HS 800H 800HS ePLC...

Page 14: ......

Page 15: ......