Motor Timer

H2C

3

■

Characteristics

■

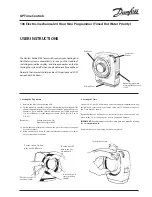

Life-test Curve

Accuracy of operating time

±

0.5% FS max.

á

±

1% max. at 0.2 to 6 s for the time range code B or at 0.5 to 12 s for the time range

code C)

Setting error

±

2% FS max.

Reset time

0.5 s max.

Influence of voltage

±

1% FS max.

Influence of temperature

±

2% FS max.

Insulation resistance

100 M

Ω

min. (at 500 VDC)

Dielectric strength

2,500 VAC, 50/60 Hz for 1 min (between current-carrying and non-current-carrying parts)

2,000 VAC, 50/60 Hz for 1 min (between contact and control circuit and between contacts of different

polarities)

1,000 VAC, 50/60 Hz for 1 min (between non-continuous contacts)

Vibration resistance

Destruction:

10 to 55 Hz with 0.375-mm single amplitude for 1 h each in three directions

Malfunction:

10 to 55 Hz with 0.25-mm single amplitude for 10 min each in three directions

Shock resistance

Destruction:

1,000 m/s

2

Malfunction:

150 m/s

2

Ambient temperature

Operating:

–10

°

C to 50

°

C

Storage:

–25

°

C to 65

°

C

Ambient humidity

Operating: 45%

to

85%

Life expectancy

Mechanical:

10,000,000 operations min. (under no load at 1,800 operations/h)

Electrical:

500,000 operations min. (3 A at 250 VAC, resistive load at 1,800 operations/h)

See

Life-test Curve

for other details.

Motor life expectancy

20,000 h

Approved standards

UL917, CSA C22.2 No.14.

Conforms to EN61812-1 and IEC60664-1 4 kV/1 (except for H2C-F

@

models).

Output category according to EN60947-5-1 (except for H2C-F

@

models).

EMC (except for H2C-F

@

models)

(EMI)

EN61812-1

Emission Enclosure:

EN55011 Group 1 class A

Emission AC Mains:

EN55011 Group 1 class A

(EMS)

EN61812-1

Immunity ESD:

IEC61000-4-2:

6 kV contact discharge (level 3)

8 kV air discharge (level 3)

Immunity RF-interference from AM Radio Waves: IEC61000-4-3: 10 V/m (80 MHz to 1 GHz) (level 3)

Immunity Burst:

IEC61000-4-4:

2 kV power-line (level 3)

2 kV I/O signal-line (level 4)

Immunity Surge:

IEC61000-4-5:

1 kV line to line (level 3)

2 kV line to ground (level 3)

Case color

Light gray (Munsell 5Y7/1)

Degree of protection

IP40 (panel surface)

Weight

H2C series:

approx. 180 g

H2C-F series: approx. 270 g

300

200

100

50

40

30

20

10

5

1

2

3

4

5

6

300

200

100

50

40

30

20

10

5

1

2

3

4

5

6

Switching oper

ations (x 10

4

)

Load current (A)

Switching oper

ations (x 10

4

)

Load current (A)

250 VAC cos

φ

= 1

24 VDC cos

φ

= 1

250 VAC cos

φ

= 0.4

24 VDC L/R = 7 msec