4. Other

Field Service Ver.

3

.0 Jan. 200

8

46

7.

Remove ten screws [1] and remove

the punch kit [2].

4

.4.1

8

Exit roller motor/Storage paddle drive clutch/Exit upper roller/Storage pad-

dle

1.

Remove the tray unit.

See P.

31

2.

Remove the finisher unit.

See P.

34

3.

Remove the finisher unit left front

cover.

See P.

26

4.

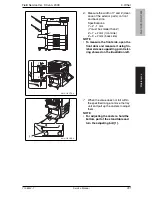

Remove eleven wire saddles [1] and

remove the edge cover [2].

5.

Disconnect three connectors [3].

6.

Remove two screws [1] and remove

the exit roller motor [2].

[1]

[1]

[1]

[1]

[2]

9J08F2C552DA

A01GF2C532DA

[1]

[3]

[3]

[3]

[2]

[1]

[1]

A01GF2C535DA

[2]

[1]

FS-519/PK-515/OT

-602

Maintenance

Service Manual Y10

8442-7