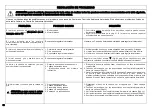

MAINTENANCE CHART

Please note that the following maintenance intervals apply for normal operating conditions only. If your daily work requires longer than normal or harsh cutting conditions are

present the suggested intervals should be shortened accordingly.

Bef

or

e

Eac

h

Us

e

Aft

er

E

ac

h

R

efu

elin

g

S

to

p

We

eh

ly

If

Da

ma

ge

d

or

Fau

lty

Inspect (Leaks, Cracks, and Wear)

X

X

Check Operation

X

X

Check Operation

X

X

Check by Dealer

X

Inspect (Leaks, Cracks, and Wear)

X

X

Inspect and Clean

X

Replace Filter Element

X

Check Output

X

X

Inspect (Damage, Sharpness, and Wear)

X

X

Check Tension

X

X

Sharpen (Check Gauge Depth)

X

Inspect (Damage and Wear)

X

X

Clean Bar groove and Oil Passages

X

Rotate, Lubricate Sprocket Nose and Deburr

X

Replace

X

Inspect (Damage and Wear)

X

Replace

X

Inspect (Damage and Wear)

X

Replace

X

Inspect (Damage and Wear)

X

X

Replace

X

Inspect - Retighten

X

Clean

X

Replace

X

Clean

X

Inspect (Damage and Wear)

X

Replace

X

Check Idle (Chain must not rotate at Idle)

X

X

Check Electrode Gap

X

Replace

X

Inspect (Damage and Wear)

x

Complete Machine

Controls (Ignition Switch, Choke Lever, Throttle Trigger, Trigger Interlock)

Chain Brake

Fuel Tank and Oil Tank

Fuel Filter

Chain Lubrication

Saw Chain

Guide Bar

Rim Sprocket (replace with every new chain)

Clutch Drum

Chain Catcher

All Accessible Screws and Nuts (not Adjusting Screws)

Air Filter

Cylinder Fins and Starter System Vents

Starter Rope

Carburetor

Spark Plug

Vibration Mounts

53

Summary of Contents for GS 650

Page 64: ...Nota 64 ...

Page 67: ...Nota 67 ...