D-19

Appendix D: Interface Data

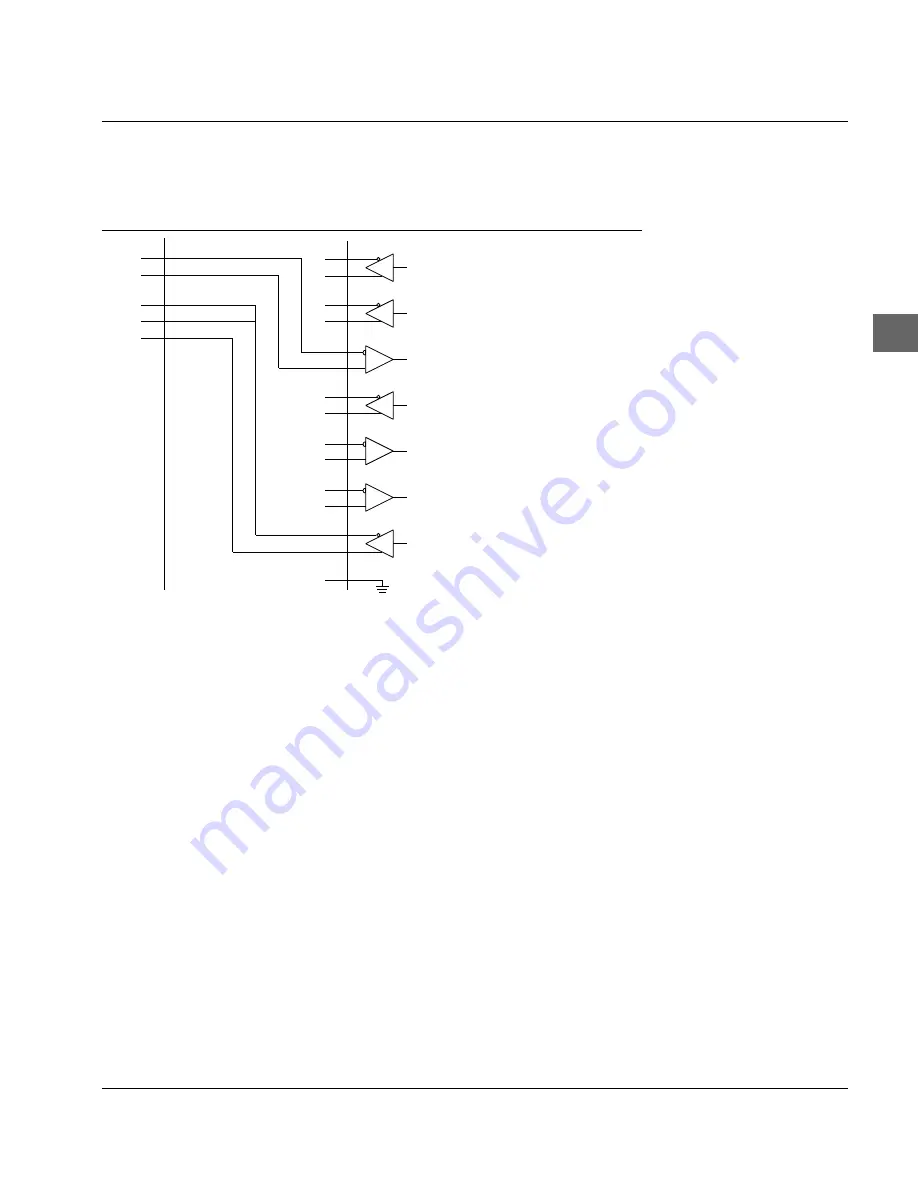

Protocol: Ready/Busy

Ready/Busy-Line (printer): SD

HP 24541B

Printer

Menu Settings

SD.A 9

SD.B 10

CB (CTS) 5

RD.B 18

GND 19

SSD+ 3

SSD- 21

SD+ 4

SD- 22

RD+ 6

RD- 24

RS+ 7

RS- 25

CS+ 9

CS- 27

DM+ 11

DM- 29

TR+ 12

TR- 30

–

+

–

+

–

+

CC (DSR) 6

DTR

Ready/Busy

Serial I/F Option Protocol

Busy Line

DSR Signal

Invalid

In this circuit (connection of a HP 24541B interface board with RS-

422A-Interface of the printer) the ports SD.A, Pin 9 and SD.B, Pin 10 are

connected to the ports RD+, Pin 6 and RD-, Pin 24 of the printer inter-

face. These are the two lines for the transmission of the print data.

The two lines for the Ready/Busy-Signal are created by connecting

ports CB (CTS), Pin 5 and RD.B, Pin 18 to the ports TR+, Pin 12 and

TR-, Pin 30 of the printer interface. Additionally a connection to CC

(DSR), Pin 6, is established on the host side from CB (CTS), Pin 5.

Looking at the two Ready/Busy-lines please note the following: al-

though the port RD.B, Pin 18 on the host side is specific for the RS-

422A interface, the second line is connected to the ports CB (CTS),

Pin 5 and CC (DSR), Pin 6 of the RS-232C interface. This ensures the

correct transmission of data with many applications, but it cannot

be guaranteed for all applications.

When printer and software status signals X-ON and X-OFF are

evaluated by an application while this circuit example is used, the

correct data transmission with this type of interface board on the

host side is not possible.

Diagram 6

Summary of Contents for ML3390

Page 1: ...User Manual MICROLINE 3390 3391 IBM EPSON compatible People to People Technology...

Page 3: ...II...

Page 7: ...VI...

Page 347: ...Z 1 Declaration of Conformity CE...

Page 348: ...Z 2 Declaration of Conformity CE...